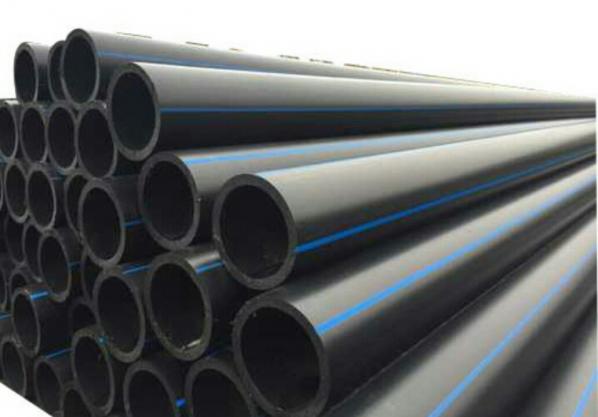

Polyethylene pipes, commonly known as PE in the marketplace and among academics, are a response to the costs of plumbing. Polyethylene pipe, which has a lifetime of nearly 100 years underground, can reduce the cost of pipe burial, which accounts for 60 to 70 percent of the cost of piping. Primary ointment PE is manufactured in various grades, currently polyethylene raw materials are manufactured in PE 80 and PE 100 grade and worldwide polyethylene pipe with PE 120 grade materials has also started.Application of polyethylene pipe in municipal and home sewage, plant irrigation, garden and orchard irrigation, use in drip irrigation, sprinkler irrigation, urban potable water transfer, gas transmission, etc.In this article we talk about polyethylene pipe price list.

- What is polyethylene pipe used for?

- High-density pipes and their properties

- Is it good to use polyethylene pipes in factories?

- What are the best industrial plastic pipes?

- Is polyethylene harmful to humans?

- Why is polyethylene bad for the environment?

- Why is polyethylene stronger than polypropylene?

- Price list of plastic pipes in 2019

- Estimate prices of polyethylene pipes in 2020

What is polyethylene pipe used for?

The special features of polyethylene pipes make it useful in water supply and gas pipes. Polyethylene pipes can be used in water, sewage, and gas transmission pipes for pressure transmission line distribution networks.In addition to their scientific name, polyethylene pipes have a brand name that is on the stock market. HDPE pipe catalogue is a type of polyethylene pipe used in gas transmission piping network, which is the best option for gas piping due to its high tensile strength and high moisture resistance.LDPE is another type of polyethylene pipe used in agricultural irrigation with drip irrigation systems. Note that the refining complexes of these pipes are very effective in their quality.The use of polyethylene pipes has grown dramatically over time, and this increasing growth has led to the development of a new generation of high grade polyethylene pipes due to the use of new technologies in the manufacture of better quality polyethylene raw materials. .

The special features of polyethylene pipes make it useful in water supply and gas pipes. Polyethylene pipes can be used in water, sewage, and gas transmission pipes for pressure transmission line distribution networks.In addition to their scientific name, polyethylene pipes have a brand name that is on the stock market. HDPE pipe catalogue is a type of polyethylene pipe used in gas transmission piping network, which is the best option for gas piping due to its high tensile strength and high moisture resistance.LDPE is another type of polyethylene pipe used in agricultural irrigation with drip irrigation systems. Note that the refining complexes of these pipes are very effective in their quality.The use of polyethylene pipes has grown dramatically over time, and this increasing growth has led to the development of a new generation of high grade polyethylene pipes due to the use of new technologies in the manufacture of better quality polyethylene raw materials. .

Polyethylene pipe has been used in various industries in Europe and then in the United States for about 5 years. Current applications include polyethylene pipe water transfer (water supply systems, pressure irrigation, etc.), chemical fluid transfer and displacement, cooling and heating fluids, use as protective coating and insulation of cables and optical fiber and various uses and He mentioned other different.Single wall polyethylene pipe is one of these pipes that can be used in pressures between 2 and 3 atmospheres (depending on raw materials, diameter and thickness of pipe) in different industries. The unique characteristics of PE pipes compared to other types of pipes (steel, asbestos, etc.) have led to a faster growth rate of these pipes in transmission and distribution networks and under pressure irrigation systems.Polyethylene pipes, also known as hard polyethylene (hdpe pipe welding) or polyethylene, are widely used in agriculture, irrigation, water supply, coating and gas transmission and transmission.

High-density pipes and their properties

The varying use of carrageenan pipe in industry and urbanization has made most people want to know the characteristics of this pipe. The differences that this tube has with other tubes make the choice between the different types of tubes, so it is necessary to find out more about it. What is a karugite tube and why is it used and why is it so popular? Corrugated pipe is an example of high performance pipes that has gained a lot of fans today. The unique structural features of this tube make it popular. It is one of a kind of double-walled pipes made of polyethylene. It has two walls and its outer surface is spiral, while its inner surface is polished, smooth and integrated, which is used for fluid passages with acidic wastewater, game, and industrial wastewater. This pipe is also known as sewage polyethylene pipes. Carrogite pipes are used in many cases that are most used in industry and urban planning. Its volume has made people interested in the features of this product. Basically, the distinction between the carogite tube, the inner surface of yellow and the outer wall of black. This type of pipe has two walls which leads to its use underground. The tube has a smooth, grooved inner surface that allows the material to move quickly without pressure, essentially letting the material in. It ranges from industrial wastewater to municipal sewage. On the other hand, the outer surface has large grooves that will increase pipe resistance.

The varying use of carrageenan pipe in industry and urbanization has made most people want to know the characteristics of this pipe. The differences that this tube has with other tubes make the choice between the different types of tubes, so it is necessary to find out more about it. What is a karugite tube and why is it used and why is it so popular? Corrugated pipe is an example of high performance pipes that has gained a lot of fans today. The unique structural features of this tube make it popular. It is one of a kind of double-walled pipes made of polyethylene. It has two walls and its outer surface is spiral, while its inner surface is polished, smooth and integrated, which is used for fluid passages with acidic wastewater, game, and industrial wastewater. This pipe is also known as sewage polyethylene pipes. Carrogite pipes are used in many cases that are most used in industry and urban planning. Its volume has made people interested in the features of this product. Basically, the distinction between the carogite tube, the inner surface of yellow and the outer wall of black. This type of pipe has two walls which leads to its use underground. The tube has a smooth, grooved inner surface that allows the material to move quickly without pressure, essentially letting the material in. It ranges from industrial wastewater to municipal sewage. On the other hand, the outer surface has large grooves that will increase pipe resistance.

The outer wall of the carotid tube has concentric conglomerates or rings, while the inner wall surface of the tube is perfectly flat. The inner wall of the carogite tube can be made of steel or heavy polyethylene (H.D.P.E). The HDPE carridge pipe is either a corrugated or spring-shaped pipe with a set of parallel lines and grooves on its surface. The reason for its corrugation is its increased resistance to high-pressure external currents and greater resistance to stress. The H.D.P.E cartridge tube is made of high-density polyethylene (HDPE), a versatile material and has some of the ideal properties for use in underground applications. This pipe is easily cut using tools and cutters.

Is it good to use polyethylene pipes in factories?

The use of polyethylene pipes is very common in factories.Polyethylene pipes have been manufactured in many different types since their inception, and there is a great deal of interest in polyethylene pipes due to their unique advantages. Here are some of the most obvious benefits of polyethylene pipes. It should be noted that these advantages are only part of the excellent specifications and benefits of PE and for each of these applications many advantages can be mentioned.

The use of polyethylene pipes is very common in factories.Polyethylene pipes have been manufactured in many different types since their inception, and there is a great deal of interest in polyethylene pipes due to their unique advantages. Here are some of the most obvious benefits of polyethylene pipes. It should be noted that these advantages are only part of the excellent specifications and benefits of PE and for each of these applications many advantages can be mentioned.

- Galvanic corrosion resistance

- Resistance to rot, abrasion and impact

- Proper flexibility

- The shrinkage property

- Light weight

- Excellent resistance to earthquakes and landslides

- Highly durable, leak-free, yet flexible connection

- High resistance to ultraviolet radiation from the sun

- Very good hydraulic properties

- Low maintenance cost

This feature is actually the most important reason for using these pipes in the sea because the combination of air and water, especially seawater, is very corrosive to conventional metal pipes. It is worth noting that galvanic corrosion of polyethylene pipes is almost zero. This property, together with the previous properties, significantly increases the useful life of these pipes compared to pipes and others. One example is a project implemented in Oman in 1996 for the Shell group. The project was replaced by a 19-km long corrosion-damaged carbon-steel pipeline with PE 100 (Water / Crude) grade polyethylene pipes.

What are the best industrial plastic pipes?

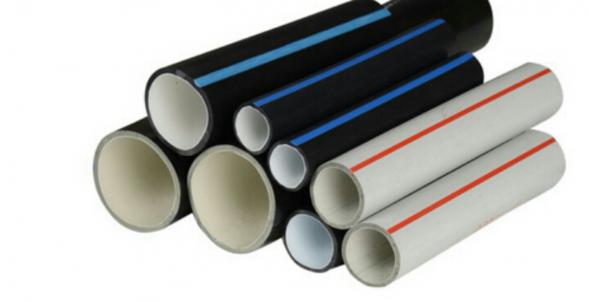

The best polyethylene pipe should have the following characteristics.In general, the following benefits to the general public of plastic pipes are as follows:

The best polyethylene pipe should have the following characteristics.In general, the following benefits to the general public of plastic pipes are as follows:

- Corrosion resistance:Plastic pipes do not corrode most of the chemicals present in domestic wastewater and also have minimal resistance to the passage of other wastewater and other fluids due to the smooth surface. These pipes will never rust and will not corrode.

- Lightness and ease of transportation:In addition to ease of transportation and cost reduction, in the case of plastic pipes, cutting, joining and installation are much easier than other types of pipes such as metal pipes.

- Flexibility and toughness:Particularly in underground applications, the flexibility of plastic pipes reduces the number of connections and easily curves piping paths.

- Various connection methods:In general, plastic pipes have the ability to thread, flange, heat weld, glue, compressor and so on and provide a wide variety of connections for different conditions.

- Excellent Hydraulic Properties: Plastic pipes fall into the group of flat surface pipes, which results in the least energy required to transport various fluids.

- Lower life and cost of installation and maintenance:Plastic pipes have been used in most cases for more than 22 years and have not yet reached the end of their life. On the other hand, they cost less during the purchase period due to lower purchase, installation and maintenance costs. Useful. Limitations The first major limitation of plastic tubes is their strength and low rigidity. In the next step, these tubes are susceptible to high temperatures.

Is polyethylene harmful to humans?

The disadvantages of polyethylene pipes should be carefully and cautiously investigated, the advantages of polyethylene pipes are so great that they are difficult to get into, but if and when faced.Have you ever seen a producer of polyethylene pipes tell about the disadvantages of polyethylene pipes and publish them on their site? The purpose of this work is to enlighten designers and interested people. The general and engineering properties of polyethylene pipes can be controlled by standards and on the other hand, in many applications due to the overlap of properties between different polymers, there can be several choices. Therefore, it is necessary to fully understand the position of the user and to master the different properties of the various types of plastic pipes. Polyethylene pipes should be used properly and for proper use so that these pipes have the best efficiency and have a useful life.

The disadvantages of polyethylene pipes should be carefully and cautiously investigated, the advantages of polyethylene pipes are so great that they are difficult to get into, but if and when faced.Have you ever seen a producer of polyethylene pipes tell about the disadvantages of polyethylene pipes and publish them on their site? The purpose of this work is to enlighten designers and interested people. The general and engineering properties of polyethylene pipes can be controlled by standards and on the other hand, in many applications due to the overlap of properties between different polymers, there can be several choices. Therefore, it is necessary to fully understand the position of the user and to master the different properties of the various types of plastic pipes. Polyethylene pipes should be used properly and for proper use so that these pipes have the best efficiency and have a useful life.

Why is polyethylene bad for the environment?

Polyethylene plastic pipes and fittings are widely used today to transport various types of gases and liquids. Polyethylene is preferred over metal because of its inherent advantages such as light weight, high flexibility, easy installation and non-changeable nature. In addition, polyethylene pipe fittings are generally less expensive and more resistant to corrosion and scaling than other pipes. In the past due to the chemical reaction of the ingredients of old and traditional fittings, there were negative effects on the smell, color and taste of drinking water. For this reason, extensive research has been carried out on selecting the best pipes for pipeline water transfer and the results show the high performance of copper pipes as well as high density polyethylene (HDPE) pipes in this area. Continue to partner with Tosun Sanat Apadana in producing and supplying polyethylene pipes, irrigation pipes, irrigation strips and pipes to learn more about the use of polyethylene pipes in drinking water consumption.In this regard, the EPA regulates standards and regulations regarding levels of contamination in drinking water distribution systems. Drinking water standards include a long list of pollutants and the maximum permissible level (maximum level of contamination or MCL) for drinking water. In fact, the Certificate (NSF 61) is recognized as the minimum requirement for the safety of materials in contact with drinking water, (NSF 14) is also another specialty certification of polyethylene pipes which is widely referred to as It is recognized, and most countries around the world have adopted it as a requirement for residential plumbing. Even today, polyethylene is used even for food containers such as milk bottles and food-grade plastic bags.

Polyethylene plastic pipes and fittings are widely used today to transport various types of gases and liquids. Polyethylene is preferred over metal because of its inherent advantages such as light weight, high flexibility, easy installation and non-changeable nature. In addition, polyethylene pipe fittings are generally less expensive and more resistant to corrosion and scaling than other pipes. In the past due to the chemical reaction of the ingredients of old and traditional fittings, there were negative effects on the smell, color and taste of drinking water. For this reason, extensive research has been carried out on selecting the best pipes for pipeline water transfer and the results show the high performance of copper pipes as well as high density polyethylene (HDPE) pipes in this area. Continue to partner with Tosun Sanat Apadana in producing and supplying polyethylene pipes, irrigation pipes, irrigation strips and pipes to learn more about the use of polyethylene pipes in drinking water consumption.In this regard, the EPA regulates standards and regulations regarding levels of contamination in drinking water distribution systems. Drinking water standards include a long list of pollutants and the maximum permissible level (maximum level of contamination or MCL) for drinking water. In fact, the Certificate (NSF 61) is recognized as the minimum requirement for the safety of materials in contact with drinking water, (NSF 14) is also another specialty certification of polyethylene pipes which is widely referred to as It is recognized, and most countries around the world have adopted it as a requirement for residential plumbing. Even today, polyethylene is used even for food containers such as milk bottles and food-grade plastic bags.

Governments in developed and developing countries and safety organizations around the world apply water quality laws. Most of these laws address the issues of chemical reaction in the environment and changing the nature of pipes and their impact on the health of drinking water and require some type of certification test, according to advertisements provided by PE manufacturers. The formulations provided for HDPE pipes have acceptable standards and high temperature resistance for drinking water.

Why is polyethylene stronger than polypropylene?

Polyethylene and polypropylene are thermoplastic and semi-crystalline polyolefins that are widely used in various industries.In many industries, both can be used, but what is the best option? Here are some hints that can help you make the best choice for your industry.The main difference between the two polymers comes from their monomeric units. The monomeric units of polyethylene and polypropylene are ethylene and propylene, respectively.Initially, the key points for the specialized selection of base polymer are stated:Polypropylene is stiffer than polyethylene and is more commonly used to produce molded parts.Cracking resistance is high, but polyethylene is somewhat elastic and more flexible.In polypropylene due to the low crystallinity speed, the presence of Aria Add 2450 and Aria Add 2161 nuclei will be effective, whereas in polyethylene due to the high crystallinity speed, the presence of nucleating agents is low. Therefore, it is possible to produce transparent product in polypropylene.

Polyethylene and polypropylene are thermoplastic and semi-crystalline polyolefins that are widely used in various industries.In many industries, both can be used, but what is the best option? Here are some hints that can help you make the best choice for your industry.The main difference between the two polymers comes from their monomeric units. The monomeric units of polyethylene and polypropylene are ethylene and propylene, respectively.Initially, the key points for the specialized selection of base polymer are stated:Polypropylene is stiffer than polyethylene and is more commonly used to produce molded parts.Cracking resistance is high, but polyethylene is somewhat elastic and more flexible.In polypropylene due to the low crystallinity speed, the presence of Aria Add 2450 and Aria Add 2161 nuclei will be effective, whereas in polyethylene due to the high crystallinity speed, the presence of nucleating agents is low. Therefore, it is possible to produce transparent product in polypropylene.

Price list of plastic pipes in 2019

The price of PE pipe varies with the type of raw materials (imported and domestic) of the material grade and the purity of the raw material of PE production. The purity of the material is the amount of raw material used in the production of polyethylene pipe with scrap materials, does not use any waste material in its production of PE and is committed to the excellent quality and production of excellent polyethylene pipe, and these companies have tested all PEs. Approved and proven high quality products. To obtain the price of PE pipes and to use the PE pipes correctly use the following:

The price of PE pipe varies with the type of raw materials (imported and domestic) of the material grade and the purity of the raw material of PE production. The purity of the material is the amount of raw material used in the production of polyethylene pipe with scrap materials, does not use any waste material in its production of PE and is committed to the excellent quality and production of excellent polyethylene pipe, and these companies have tested all PEs. Approved and proven high quality products. To obtain the price of PE pipes and to use the PE pipes correctly use the following:

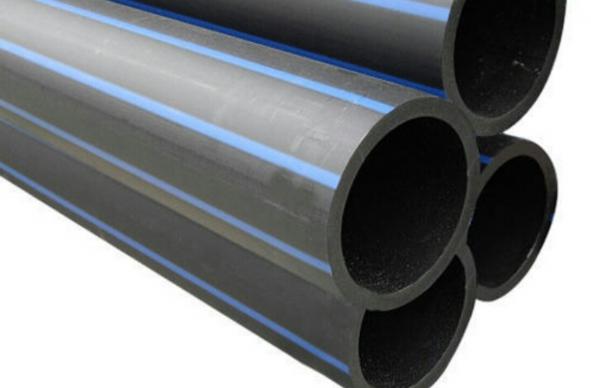

The cost of this product depends on the diameter and pressure of the pipe as well as its raw materials, and these pipes have different lengths, usually starting from 20 mm and eventually leading to 2400 mm in massive designs. Price of PE pipe and its weight Directly with the working pressure of the pipe, the higher the pressure, the higher the pipe weight and hdpe pipe prices. Purchase of this product and polyethylene fittings, hdpe pipe manufacturers plant equipment, factory reputation and reputation should be taken into consideration.

Estimate prices of polyethylene pipes in 2020

Polyethylene pipes are made of polyethylene materials that the price of these materials in the stock market is constantly changing and there is no relative stability in the price of polyethylene pipes, so after receiving the price per kg of polyethylene pipes that price in weight Multiply any given size of pipe that can consist of PE 80 or PE 100 and then show the price obtained per meter of pipe in question.

Polyethylene pipes are made of polyethylene materials that the price of these materials in the stock market is constantly changing and there is no relative stability in the price of polyethylene pipes, so after receiving the price per kg of polyethylene pipes that price in weight Multiply any given size of pipe that can consist of PE 80 or PE 100 and then show the price obtained per meter of pipe in question.

That is, based on the type of raw material PE80 or PE100, the price of a polyethylene pipe is obtained by multiplying the price of each kilo of raw material in the weight table above, expressed as KG / M.Polyethylene pipes, as the name implies, are made from polyethylene raw materials and the price of these raw materials is fluctuating relative to the price of oil on world markets, with the increase in the price of barrels of oil in world markets for petrochemical products. Price and inflation will face.

I am glad that I found your website; it has just the right pipes that I was looking for!

How can I order?

Hi dear Monroe!

please fill out the inquiry form on our website to contact us.

what is the best cbd oil for chronic pain

Your comment submitted.