Given the increasing use of plastic pipes in industrial installations and buildings and the production and distribution of various types of plastic pipes with different names and generations as the petrochemical industry develops, selecting and buying the most suitable Plastic pipe type is not easy for a particular application and requires studying and understanding the common types of these pipes.

- Wide Range of Polyethylene Pipes in The Pipe Stores

- Best manufacturers of polyethylene pipes in Asia

- Most famous brands of pipes in the world

- Which pipes are more stornger?

- Most important tips in buying polyethylene pipes

- Is exporting pipes profitable?

- Best discounts stores of poly pipes near me

- Affordable prices of pipes for exporting to different countries

- HDPE pipes companies and suppliers in USA

One of the most common and widely used types of plastic pipes are polyethylene pipes. One of the most common and widely used types of plastic pipes are polyethylene pipes. Nowdays, with the increasing use of these pipes, the Polyethylene Pipe Manufacturers are also increasing day by day and have created a lucrative business.

Wide Range of Polyethylene Pipes in The Pipe Stores

The use of plastic pipes in installations dates back to the mid-1930s. For the first time, the Germans used plastic pipes for drainage systems. Subsequently, the recognition of more and more disadvantages and disadvantages of steel pipes led to the replacement of plastic pipes over time and in many cases.

The use of plastic pipes in installations dates back to the mid-1930s. For the first time, the Germans used plastic pipes for drainage systems. Subsequently, the recognition of more and more disadvantages and disadvantages of steel pipes led to the replacement of plastic pipes over time and in many cases.

The most important disadvantages of metal pipes are corrosion, internal surface deposition, high weight, transportation and installation problems (compared to plastic pipes).

The growing trend in the use of plastics and in particular polyethylene (HDPE) in the industry is due to the properties and applications of these materials and their applications, which has led to a remarkable improvement in production and workability in various industries over a short period of time. To be a witness.

Over the past fifty years, the industry, with advances in the production of hdpe pipes and hdpe pipe fittings, has introduced itself as a suitable replacement for steel pipes, PVC, GRP and cast iron and has been able to, in most cases, As a replacement for such pipes, project managers are often pleased to accept this replacement (polyethylene pipe with other pipes). This decision has been very effective.

Due to the many advantages and benefits of polyethylene pipes, these pipes have played a very important role in the industry and everything related to pipes and fittings. The hdpe pipe suppliers near me are making a huge profit from this. Therefore, the widespread existence of these types of plastic pipes is neglected by shops and stores and their important role in the market.

Best manufacturers of polyethylene pipes in Asia

High quality is the criterion for determining the best PE pipe and the best pipe in Asia, and quality is not an accident, it is the result of a process of hard work carried out in a manufacturing unit, producing a unique and unique product of its kind. Is. The best polyethylene pipe factory in Asia is always at risk of threats, counterfeit goods, bad quality competitors, etc. To determine the best manufacturer or factory, it is best to take action yourself and buy the PE pipe and do the necessary research. . Polyethylene pipe is 50 to 100 years shelf life and for this longevity must be an expert work to identify the best PE pipe, so visit the process of PE production to select the best product and a reasonable and admirable purchase Perform specific inspections during pipe manufacturing to ensure that your order is properly manufactured.

High quality is the criterion for determining the best PE pipe and the best pipe in Asia, and quality is not an accident, it is the result of a process of hard work carried out in a manufacturing unit, producing a unique and unique product of its kind. Is. The best polyethylene pipe factory in Asia is always at risk of threats, counterfeit goods, bad quality competitors, etc. To determine the best manufacturer or factory, it is best to take action yourself and buy the PE pipe and do the necessary research. . Polyethylene pipe is 50 to 100 years shelf life and for this longevity must be an expert work to identify the best PE pipe, so visit the process of PE production to select the best product and a reasonable and admirable purchase Perform specific inspections during pipe manufacturing to ensure that your order is properly manufactured.

Note that the price list for PE is never a suitable factor in selecting pipes manufactured in a factory and no other product!

Most famous brands of pipes in the world

In order to determine the best brand of pipe, it is best to have complete knowledge of the entire pipe manufacturing process as well as the raw materials used in it. The best pipe marking should have some specifications. The pipe must have a standard badge and the manufacturer has manufactured the pipe according to INSO 14427-2. Also on the pipe the date of production of the pipe is fully inserted and other pipe information can also be clearly identified, type of raw material, extruder line number of the pipe manufacturer, the word Masterbatch (if the pipe is a material combination). White polystyrene and masterbatch manufactured), consumption and application of polyethylene pipe.

In order to determine the best brand of pipe, it is best to have complete knowledge of the entire pipe manufacturing process as well as the raw materials used in it. The best pipe marking should have some specifications. The pipe must have a standard badge and the manufacturer has manufactured the pipe according to INSO 14427-2. Also on the pipe the date of production of the pipe is fully inserted and other pipe information can also be clearly identified, type of raw material, extruder line number of the pipe manufacturer, the word Masterbatch (if the pipe is a material combination). White polystyrene and masterbatch manufactured), consumption and application of polyethylene pipe.

The best mark of the pipe must be manufactured by a reputable manufacturer and the manufacturer can submit certificates related to its production and can be seen on the site. The best pipe marking is provided by the manufacturer and seller who provide the customer with complete information and provide all contractor installation instructions and procedures.

The manufacturing process is very important and the quality of the pipe is important in the manufacturing process. The quality of the best pipe is primarily related to the type of raw material used, the quality of the pipe used is not recyclable and waste at all, and all new and used materials are used. The standard text states that the same pipe materials can be produced at a rate of 5%, but waste is not used to produce the best quality pipe and pipe.

The best pipe, apart from the use of the proper raw materials, must be manufactured by modern and equipped equipment and production lines that produce the pipe in the best possible manner and have a perfectly smooth surface. The pipeline works like a single body and must work in harmony with each other to ensure that the pipe is of high quality.

Which pipes are more stornger?

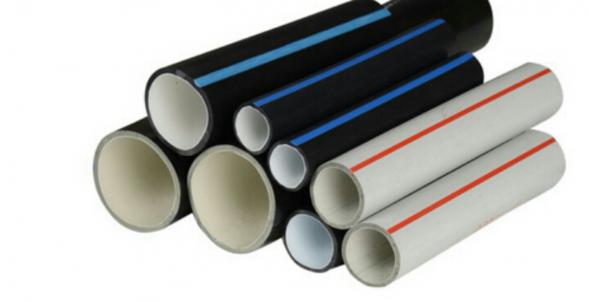

Pipes have many different types. With the proliferation of plastic pipes and its widespread production around the world, if we want to ignore other types of pipes and focus on plastic pipes, these pipes are often polymeric. The most common and well-known polymers used for the manufacture of plastic pipes (which are called poly pipes) are :

Pipes have many different types. With the proliferation of plastic pipes and its widespread production around the world, if we want to ignore other types of pipes and focus on plastic pipes, these pipes are often polymeric. The most common and well-known polymers used for the manufacture of plastic pipes (which are called poly pipes) are :

- Polyvinyl Chloride (PVC pipe)

- Polyvinyl Chloride (CPVC pipe)

- Polyethylene (PE pipe)

- Polypropylene (PP pipe)

- Acrylonitrile butadiene styrene (ABS)

- Glass fiber reinforced plastic (GRP)

It is clear that the use and performance pipes will vary according to their gender. Therefore, when preparing the desired pipe, we first need to consider our intended use and then purchase. Each of the pipes introduced has specific features that are tailored to suit specific applications. But if you want to test them for strength, polyethylene pipes have the best strength and resistance.

This polymer (PE) has good strength and good impact resistance. There are now many factories in the world producing PE pipes, and it should not be forgotten that these pipes are different in terms of raw materials, manufacturing methods and quality control, and therefore not of the same quality and quality.

One of the well-known types of PE pipe is the Cross-Linked Polyethylene pipe which can withstand high temperatures and relatively high pressures up to (100 Psig). And today these pipes are often used for floor heating systems.

It is also worth noting that polypropylene (PP) pipes are also strong pipes. Thermoplastic polypropylene is of relatively high strength. Travel bags, for example, are mainly made of polypropylene.

Most important tips in buying polyethylene pipes

When purchasing polyethylene pipes it should be borne in mind that the pipes manufactured must be of the first class material, otherwise the pipe may be compressed by pressure. It is very difficult to determine whether the tubes are made of premium materials or that they are made of non-standard materials such that even many marketers and individuals who have been producing, buying and selling polyethylene pipes for many years. Can not recognize. But companies that produce polyethylene pipes with non-standard materials usually do not have the standard and try to avoid standard marking on the pipes.

When purchasing polyethylene pipes it should be borne in mind that the pipes manufactured must be of the first class material, otherwise the pipe may be compressed by pressure. It is very difficult to determine whether the tubes are made of premium materials or that they are made of non-standard materials such that even many marketers and individuals who have been producing, buying and selling polyethylene pipes for many years. Can not recognize. But companies that produce polyethylene pipes with non-standard materials usually do not have the standard and try to avoid standard marking on the pipes.

Also, due to the lack of use of PE materials and the inability of PE production machines, the molded pipes do not have a smooth, smooth surface and are similar to orange peel grain because of the use of PE. Previously used in manufacturing are recyclables. Also, these pipes do not melt well because of the reason that there is air between the pipes and if the water is pushed into the pipes they will cause the pipes to break.

These types of pipes are mostly used as coverings and sheaths for wires and cables and telecommunication cables and since they cannot withstand internal pressure (load) when used in drip irrigation systems, under pressure and. .. are simply combined. They are also shorter in life due to the use of recyclables as well as the lack of proper baking and are used in temporary pipelines.

Therefore, when purchasing these pipes, you should consult with experts before purchasing the information you need, either by querying people or by searching the internet. Don’t be fooled by the low price of products

Is exporting pipes profitable?

Exports of pipes and fittings as one of the most demanding steel products on the one hand, and on the other hand, fluctuations in the dollar and the currency, instantaneous customs rules, etc. have created their own problems that require specialized and specialized experts in this field. However, nowadays the export of these products has become one of the most lucrative and profitable businesses due to the extreme need for pipe and fittings worldwide.

Exports of pipes and fittings as one of the most demanding steel products on the one hand, and on the other hand, fluctuations in the dollar and the currency, instantaneous customs rules, etc. have created their own problems that require specialized and specialized experts in this field. However, nowadays the export of these products has become one of the most lucrative and profitable businesses due to the extreme need for pipe and fittings worldwide.

Refer to the relevant websites for export pipe prices. You can also read export processes, export bans, worldwide pipe exporting factories, commercial services, and other information on exporting pipes on the Business Services and Export Articles website.

Best discounts stores of poly pipes near me

The best discount pipes and fittings stores must have a wealth of experience in supplying, distributing and selling pipe and fittings. These stores, having the ability to sell the majority of domestically produced corporate brands and reputable brands in the industry, meet their expert and specialized team of consumer and specialist market needs for sewage, polycarbonate, pipes and fittings. , Polyethylene, polypropylene and 5-layer pipe. These stores should also be ready to work with companies, institutions, public and private organizations, as well as mass producers. Due to the increasing importance of cyberspace and the expansion of business space in this field, Pipe & Fittings Store should strive to provide good quality and quality by launching dedicated website, sales and service, and always strive for good reputation. It remains in the market for pipes and fittings. Continuous customer support before and after the purchase, the ability to purchase a variety of different brands, and the convenience of the different prices and facilities intended for customers, are among the best working and performing stores for pipe and fittings.

The best discount pipes and fittings stores must have a wealth of experience in supplying, distributing and selling pipe and fittings. These stores, having the ability to sell the majority of domestically produced corporate brands and reputable brands in the industry, meet their expert and specialized team of consumer and specialist market needs for sewage, polycarbonate, pipes and fittings. , Polyethylene, polypropylene and 5-layer pipe. These stores should also be ready to work with companies, institutions, public and private organizations, as well as mass producers. Due to the increasing importance of cyberspace and the expansion of business space in this field, Pipe & Fittings Store should strive to provide good quality and quality by launching dedicated website, sales and service, and always strive for good reputation. It remains in the market for pipes and fittings. Continuous customer support before and after the purchase, the ability to purchase a variety of different brands, and the convenience of the different prices and facilities intended for customers, are among the best working and performing stores for pipe and fittings.

You can find the best discount pipe and pipe fittings stores near you by searching the Internet and finding the address of the store. You can also shop online for the information you need instead of visiting

Affordable prices of pipes for exporting to different countries

As mentioned, the price of a commodity is never a suitable component for choosing that commodity. A simple calculation can be a bit helpful, how and how is the price of a good pipe, for example good, lower than its raw material price? Are pipes not made of the same materials? Has shipping and production costs been added to it? By asking these questions and trying to find the right answer, you can see that waste material is used in the production of such pipes and that waste pipe is never a good quality pipe and will not be in your project. It has some basic problems.

As mentioned, the price of a commodity is never a suitable component for choosing that commodity. A simple calculation can be a bit helpful, how and how is the price of a good pipe, for example good, lower than its raw material price? Are pipes not made of the same materials? Has shipping and production costs been added to it? By asking these questions and trying to find the right answer, you can see that waste material is used in the production of such pipes and that waste pipe is never a good quality pipe and will not be in your project. It has some basic problems.

The best prices for pipes for export to different countries of the world can be identified by 10 minutes of internet research and determine the best pipe after specifying the intended use.

HDPE pipes companies and suppliers in USA

HDPE pipes are categorized according to the strength and intensity of prior technological developments. These types of pipes have been tested in 1950s, especially in the transportation of drinking water, which has had positive results. One of the most widely used pipes today is HDPE plumbing systems, which are economically available, efficient, and easy to operate, and are very useful.

HDPE pipes are categorized according to the strength and intensity of prior technological developments. These types of pipes have been tested in 1950s, especially in the transportation of drinking water, which has had positive results. One of the most widely used pipes today is HDPE plumbing systems, which are economically available, efficient, and easy to operate, and are very useful.

Therefore, the unique benefits and features of these pipes have led many companies and suppliers in USA to invest in the field and benefit greatly from it.

The advantages and features of polyethylene pipes are summarized below and titrated below :

- Resistance to chemicals

- low weight

- High strength and flexibility and stress tolerance

- No leakage

- Impact Resistance

- Impermeability

- Wear-resistant

- Resistant to rodent and microorganism attack

- No cathodic protection and protection required

- Having a long life

- Resistant to organic solvents

- UV resistant to sunlight

- Cold and heat resistant

- Easy installation and running and easy shipping

- Ability to use a variety of connections (varied and almost unlimited connections)

Given these advantages, it seems reasonable to invest in producing hdpe pipes and setting up factories for them. The profits in this area are so great that the number of companies and factories producing polyethylene pipes and fittings is increasing in USA day by day.

Your comment submitted.