Plastic pipe structure

- Is HDPE water pipe safe to drink from?

- What pipe is best for water supply?

- Which countries have best water pipe products?

- Is it affordabel to use plastic pipes in home?

- PE pipes and their properties

- What size water pipe should we use in Houses?

- Which water pipes are more popular in the world?

- Disadvantages of metal pipes to use in home

- Price details of water pipes in Iran

Plastic Water Pipe

Plastic tubes are made of organic polymers, which behave differently against heat: 1. Thermoplastics: They are often solid at ambient temperature and are soft and ductile with increasing heat. Many plastic pipe materials include polypropylene (P.P), PVC, polyethylene (PE), thermoplastic. Thermoplastics can be reheated and re-heated. 2- Thermosets: With the increase of heat they soften and form. They become solid again and take on hardness, but the thermostats cannot be reheated and transformed into other forms. In fact, they are immutable.

Is HDPE water pipe safe to drink from?

Given the increasing use of plastic pipes in the industry and construction of the country, the variety of production and distribution of these pipes with different properties, the choice of suitable plastic pipes for a specific application makes it a specialized choice based on knowledge and science. Has become. Since the 1930s, when the Germans first used plastic pipes in building installations and to discharge wastewater, plastic pipes have become widely used today. These pipes have many advantages over metal pipes. Corrosion resistance, low weight, low deposition on the inner surfaces, easier transportation, easy installation of various types of different properties and even more beauty are the most important uses of these pipes over metal pipes. Slow. Needless to say, there are disadvantages to using these pipes, but the variety of their properties can minimize the use of a specimen for a particular application. The properties of plastic pipes vary depending on the operating conditions, service specifications and fluid used in the material. Initial depends. In general, plastics and therefore pipes made of it have good resistance to corrosive liquids and gases such as acids and salt solutions, etc. However, this resistance is directly related to the concentration of corrosive materials, temperature and pipe used. Slaves and the type of these fluids. As you know, the heat transfer capability of plastic pipes is very low, which minimizes heat loss, but it is worth noting that the high expansion coefficient of plastic pipes is one of the disadvantages of such pipes. . For example, PVC pipes expand at least five times the size of the steel, causing it to twist along the path that needs to be considered, and consider the necessary arrangements, for example, to extend it further. It requires cost.

What pipe is best for water supply?

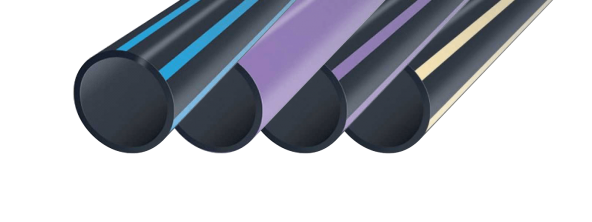

Types of plastic or polymer tubes

The most common polymer or plastic pipes available in the market are pipe and fittings, polyethylene pipes, PVC pipes, polypropylene pipes and polybutylene pipes. PE: PEs are the new generation of plastic pipes that covered the disadvantages of other pipes. Good strength and impact resistance. One of the types of PEX pipes called PEX pipes, which are reticulated polyethylene pipes, have high resistance to temperature and pressure tolerance and can be used in floor heating systems. Types of polyethylene pipes include single-walled, double-walled, spiral tubes and karogite tubes, each of which has its own application. Polyethylene pipes are very easy to connect and use different methods of flange, clamp, orientation, gear, male and pistil by the method of heat welding and head to head welding. Advantages of PE pipes: Type PE PE pipes: Low thermal resistance, good density, optimum flexibility. Type II PE pipes: Medium density, hardness and heat resistance higher than type one. Type II PE pipes: High density compared to type I and II, higher hardness and thermal resistance than type I and type II, suitable for water supply and gas supply systems.

Which countries have best water pipe products?

Polypropylene PP

plastic water pipe fittings

Polypropylene pipes are similar in use to PVC pipes but are more robust and practical in properties. Polypropylene pipes have higher impact resistance than chemicals and withstand a wide range of temperatures that can be used to transport hot and cold water. Installation is also very simple. PVC Polyvinyl Chloride PVC pipes are often light, white or gray. PVC pipes are extremely brittle at zero and below zero. Unlike other flammable plastic pipes, PVC pipes remain and disappear at the point where the flames occur and do not spread to other parts of the pipe. These pipes are exposed to extreme sunlight or ultraviolet light, lose their quality and are therefore not suitable for use in hot water pipes. Due to the high fragility, these pipes replaced the PE pipes. The best use of PVC pipes is for use in domestic water and sewage systems and business centers. The treated water should be free of hard and toxic ions. Wastewater, on the other hand, has a large amount of ions in the ions, which can damage the pipes. PVC and PVC pipes are highly resistant to acidic, inorganic and alkaline salts and are more stable so use of these pipes in the sewage and water supply system is of great importance. PVC pipes are divided into UPVC and CPVC. CPVC pipes have more chlorine than PVC pipes and are much more resistant to weather. They are also more resistant to pressure and heat. Types of PVC Pipes: Low Pressure PVC Pipes: Available in two colors: gray and blue, which are used for ventilation of rainwater and sanitary connection pipes. High Pressure PVC Pipes: Available in light gray color and is used as the main sewage collector for the building sewer system. Benefits of PVC Pipes: “Quick and easy connection” Light weight and easy execution “External diameter less than other pipes” High resistance to chemicals. Disadvantages of PVC pipes: “high frost in cold” low resistance in high heat “low resistance to external forces.

Is it affordabel to use plastic pipes in home?

Chlorine polyvinyl chloride CPVC

Chlorine polyvinyl chloride CPVC

types of plastic water pipe

Vinyl chloride pipes are similar to PVC pipes, the only difference being the amount of chlorine used in their structure. CPVC pipes are more resistant to heat, abrasion and cracking than PVC pipes. Therefore, fewer hangers and pendants are needed during installation. So they can be used in hot tub circuits in the thermal system. Also, unlike other plastic pipes, vinyl chloride does not pass oxygen and is more resistant to corrosion. It also does not spread fire and is much less harmful than other pipes. ABS Acrylonitrile Butadiene Styrene: ABS pipe is a tough polymer whose raw material is three acrylonitrile, butadiene and styrene, depending on its properties. The amount of these three substances in the tube varies. The maximum acceptable of these three materials for the production of ABS pipe include 35% acrylonitrile, 30% butadiene and 60% styrene. The ester, acetone and ketone materials have low resistance to chemicals and their walls are corroded. Therefore, the use of these pipes in the piping system of factories and refineries is not recommended. Polyethylene pipes are a better option for this application. ABS pipes are mostly used to transport neutral solid waste. Building solid waste collection channels are a good example of this application.

PE pipes and their properties

Superpipe or five layer pipes

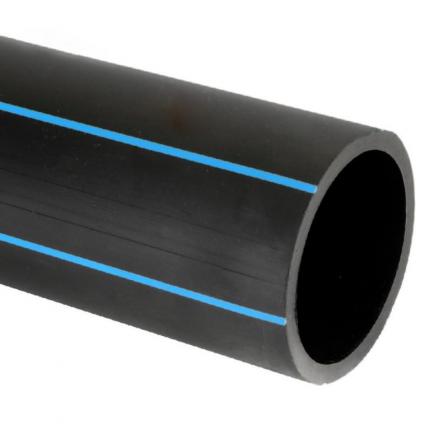

hdpe pipe

Deposition and corrosion of metal pipes have always been one of the major problems in building plumbing. Plastic tubes were formed to address these factors, and polymer tubes were expected to make the route easier, but along with these shortcomings, they themselves caused problems. Plastic tubes had difficulty penetrating oxygen, restricted to high temperature pressure, high expansion coefficient, and so on. Under these conditions, a combination of metal and polymer was proposed and all super-pipes were formed. Superpipe is a 5-layer tube consisting of one layer of aluminum, two layers of polymer and two layers of special adhesive. Superpipe tubes inherit stainless, anti-fouling, anti-corrosion and corrosion properties from polymer and receive heat resistance, high pressure tolerance and impermeability to metals. Aluminum with ultrasonic longitudinal welding forms the main body of the pipe which provides resistance to penetration, high pressure tolerance and heat. The inner and outer layers of the superpipes are made of new PEOC polymer rather than PEX lattice PEX because it has a much longer life at high pressure and temperature. The polymer and metal layers are then bonded together by a special adhesive. Benefits of Five Layer Pipes: Stainless, Sediment and Caries. High flexibility and flexibility. Easy to operate and install, fast and without waste. Very light and easy to transport. High resistance to oxygen penetration and sludge. Very small longitudinal expansion coefficient. Very low pressure drop due to smooth interior surface. Impact resistant and chemicals. Pressure resistant due to aluminum longitudinal welding. High resistance to constant heat.

What size water pipe should we use in Houses?

Plastic pipe applications

mdpe water pipe

The most important uses of plastic pipes are irrigation and drainage systems, drainage and sewage systems, water distribution and irrigation and gardening, factories and more. In recent years, with the development of polymers for the transfer of oil, gas, etc. plastic tubes have also been used. The diameter of these pipes starts from 20 mm and eventually reaches 2400 mm. The price of PE and its weight is directly related to the amount of pressure applied and the higher the pressure, the higher the weight and price of PE. As cities are growing and expanding, new ways of urbanization, such as the sewage collection and disposal system, have replaced old practices. Even in small towns, they use the sewage system if there are financial opportunities for health, environment, safety, etc. Specific types of pipes are used to collect and transport wastewater from production sites to treatment plants. These tubes can be categorized into different types in terms of sex, application and fitting. In the water supply and sewage collection, mainly iron and plastic pipes are used. Asbestos cement pipes and concrete pipes are also used to collect sewage, but these pipes are becoming extinct due to environmental problems and costly maintenance. Galvanized pipes are also used in the irrigation of homes and places and small plumbing systems.

Which water pipes are more popular in the world?

Application of PE in drainage

plastic pipe sizes

With the growth of urban living spaces and the urban and rural needs, modernizing engineering infrastructure is one of the pillars of resource management and conservation. Drainage is one of the infrastructures that have been carried out in various ways since ancient times and are of great importance. Drainage is the process of removing excess surface water and managing shallow groundwater through the maintenance, transmission, disposal and management of water quality to achieve the desired economic and social benefits, while preserving the environment.

Drainage is generally carried out to collect and manage surface and subsurface water and is used in urban structures (highways, streets, playgrounds, parks, green spaces and urban passages), farmland and even courtyards. Depending on where the drainage is to be carried out, the pipe, fittings and method of operation of the drainage system will be different, and different pipes will be needed. And the use of experienced experts. Pipes at landfill sites are of high importance, which are responsible for the transport of toxic gases and valves. Pipes used in landfills must be resistant to all kinds of chemical reactions and be able to maintain their integrity for a long time. Polyethylene pipe (HDPE) has exceptional resistance to all kinds of destructive chemicals and corrosive materials including soil and moisture (over 100 years lifespan). Polyethylene pipes are ideal pipes for use (landfill and on land) in specific soil environments such as landfills.

Disadvantages of metal pipes to use in home

Plumbing installations are the most important part of towns and villages. The safety and performance of all pipes installed in piping networks is of utmost importance. Naturally, pipes should be selected for their longevity and able to remain in the pipeline for many years. The types of pipes used in plumbing and installations must be resistant to changes in environmental conditions and maintain their properties. Carrogite was introduced to the market and soon gained immense popularity, with engineers preferring to use polyethylene pipes for installation in water and sewage networks. Polyethylene pipe and uv PVC pipe are manufactured in different sizes and sizes and each of them is selected according to the pipeline and installation project. These pipes are of different diameter and thickness and are designed to operate at different operating pressures. Currently plastic pipes are one of the most common water and sewage conveyor pipes. Double wall polyethylene pipes, including carogite pipe and spiral pipe, are used for large water and wastewater projects. Sanitary sewer transmission by plastic pipes is possible.

Price details of water pipes in Iran

Polypropylene pipes (green pipes): Polymeric pipes have many advantages over traditional pipes. The low weight, fast running, low corrosion, low sedimentation and low cost make these pipes attractive. Disadvantages are the inability to withstand high pressures and the high deformation in cold and warm temperatures that limit their use. In pipe installations, the corrosion and deposition structure of metal pipes causes damage and problems. Many efforts have been made to solve this problem. Different alloys have been coated with solutions that have been used to increase corrosion resistance of the metal so far without giving any definitive answer to the problem. Another way to avoid problems with metal pipes is to use polymer pipes, but using these pipes has shown in practice that although replacing metal with plastic solves the problem of corrosion and decay of the pipes, It causes another that did not exist before, such as oxygen diffusion, pressure or temperature limitation, high expansion factor. Newpipe, for example, is the highlight of this technology. The clever fusion of a five-layer tube consists of an aluminum tube, two layers of polymer and two layers of special adhesive – which resist corrosion, rust, deposition and decay from polymer tubes and can withstand constant heat, high pressure and It inherits impermeability from metal pipes. NuPype is the latest technology breakthrough that is applicable to all building installations and even lives a hundred years even in the worst of conditions.

I simply want to give a huge thumbs up for the great products you have sent us. I will be coming back to your website for more soon.

Your comment submitted.