pe pipes nz | Sellers at reasonable prices pe pipes nz

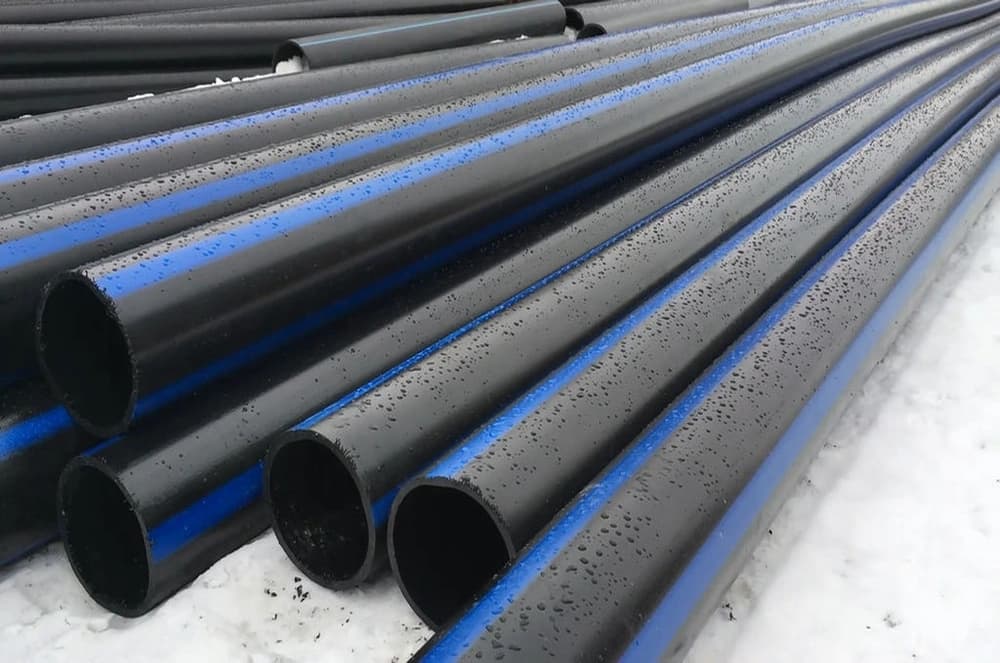

pressure specifications for pe pipes are higher than pvc pipe the basic meaning of pe pipe is poly ethylene and in terms of quality it outweighs pvc pipe

pe pipes are a wonderful alternative for farmers who wish to cultivate high-quality plants without wasting time or money

These pipes are intended to produce continuous steam flows at pressures ranging from 0-80 psi

To attain these levels of performance, PE tube plugs are made using a thicker gauge material than standard glass plugs

Additionally, pay pipes have a fixed shape and design, making them excellent for delivering precise volumes of steam at any pressure

Components used to produce PE pipes The material utilized to construct the PE pipe is crucial, especially if custom sections are to be created

A pipe of high quality should have thick glass walls, a solid base, and a sturdy stem

Numerous varieties of glass, including borosilicate, quartz, and lead crystals, can be used to manufacture PE pipes

Each variety of glass has distinct qualities and benefits

Borosilicate glass is frequently chosen because of its durability, light weight, and usability

Lead crystal is ideal for dense smoke, while quartz glass is ideal for smooth hits

If you wish to purchase pre-made pe pipes, you can opt for pipes rather than traditional bowls

thick glass walls and huge diameters of bongs make them perfect for delivering a steady amount of steam

glass density The thickness of the glass wall is another crucial consideration when selecting a pipe

Pipes with thicker glass walls are stronger than those with thinner glass walls

When purchasing prefabricated PE pipe online, the thickness of glass wall is not always clear

If you prefer to manufacture your own PE pipe, you may simply use a ruler to measure the thickness of each glass layer

polyethylene pipe specifications

generally, the basic type of pipe we are commonly familiar with is pvc

the off shoots of pvc are pe and hdpe, both of which are stronger than pvc and offer more lasting features compared to pvc

In the following you will be presented with the most common specifications and features of polyethylene pipe

The parameters for polyethylene tubes and pipes

Pipes made of polyethylene are not expensive and can be found almost anywhere

In most cases, they are utilized for reasons of irrigation

The diameter of the majority of polyethylene pipes is standardly measured at 1/2 inch (12

7 mm)

Nevertheless, there are some manufacturers that provide pipe diameters in the 3/8 range “(in the range of 9

5 mm

) to 1 inch (25

4 mm)

The sort of pipe

Pipes can be broken down into two primary categories: straight and corrugated

In most cases, irrigation systems consist of pipes that are straight

The usage of bellows is common in the field of drainage

Pipe diameter

The sizes of the pipes range from half an inch to two inches

Pipes with a smaller diameter are typically utilized for undertakings of a lesser scale

When working on larger projects, greater pipe sizes are utilized

The depth of the wall

0

005 “The wall thickness of 0

127 millimeters is adequate for the majority of residential applications

Leakage is less likely to occur when the walls are thick

Accessories

Pipes typically include threaded connections called fittings at both ends

Fittings come in a wide variety of configurations, including male and female threads, compression fittings, and slide fittings, amongst others

Accumulation

Pipe is joined together at its joint points by means of couplings

Slip joints are the most frequent type of joint, although there are many other kinds of joints

pe 100 pipe

PE100 plastic pipe is a suitable alternative to HDPE pipes and is constructed of polyethylene

Polyethylene comes in a variety of sizes, shapes and densities

It is a versatile substance used in many industries

PE100 polyethylene is exceptionally robust and flexible

It is commonly used for medical purposes and is FDA-approved

It does not discharge chemicals into the earth and is safe for food usage

HDPE pipes are often used in cannabis production and are quite durable

These pipes are made of high-density polyethylene (HDPE) plastic and offer various advantages over other types of pipes

The first advantage is its durability

HDPE pipe lasts longer than any other type of pipe and is less prone to cracking or breaking

Another excellent advantage is that they are much lighter than other types of pipes, which makes them easy to move

HDPE pipes are also biodegradable and recyclable

HDPE pipes are costlier than PE100 plastic pipes

Despite the fact that both types of pipes are affordable, HDPE pipes are more expensive due to their superior quality and durability

HDPE pipes are heavier than PE100 plastic pipes

HDPE pipe weighs approximately four pounds per foot, but PE100 weighs only one pound per foot

This means that transporting a large number of pipes will be challenging due to their weight

Pe pipes can be used for irrigation when a high resistance against pressure is needed Drip irrigation systems are the most effective method for watering plants

They allow you to control how much water each plant receives and prevent overwatering

HDPE pipes are less user-friendly than PE100 polymers

There are numerous limitations to HDPE pipes

For instance, they cannot be bent or drilled through

Additionally, you cannot connect fittings to pipe ends

until the end of the pipe is cut off

pe100 pipe specifications

The American Society for Testing and Materials developed the specifications for PE100 in the year 1998

(ASTM)

The physical qualities of polyethylene pipe are defined by this standard

These properties include the pipe’s inner diameter, wall thickness, and outside diameter

These measurements help to confirm that the pipe satisfies the minimal requirements for safe use so that it can be put into service

ASTM D-2863 is the standard that describes PE 100 pipe, and it is usually known by that name

The diameter of the pipe’s inside (PE100) The measurement taken from within the pipe is referred to as the interior diameter

When measuring the pipe, a caliper should be used

In order for the fitting to work properly, the internal diameter needs to be at least 1/8 inch greater than the exterior diameter

The PE 100 pipe has an internal diameter of 0

250 inches all the way through

The wall thickness of PE100 pipes The distance that exists between the inner surface of the pipe and the outer surface of the pipe is referred to as the wall thickness of the pipe

The pipe’s wall thickness shouldn’t be more than 0

003 inches thick at any point

When using PE100 pipe, the wall thickness should not be greater than 0

0030 inches

Diameter of the outside of PE100 The measurement of the whole circle of the pipe is referred to as the outside diameter of the pipe

Pipe specifications require that the exterior diameter be at least 0

500 inches bigger than the pipe’s internal diameter

The outside diameter of a PE100 pipe is 2

750 inches

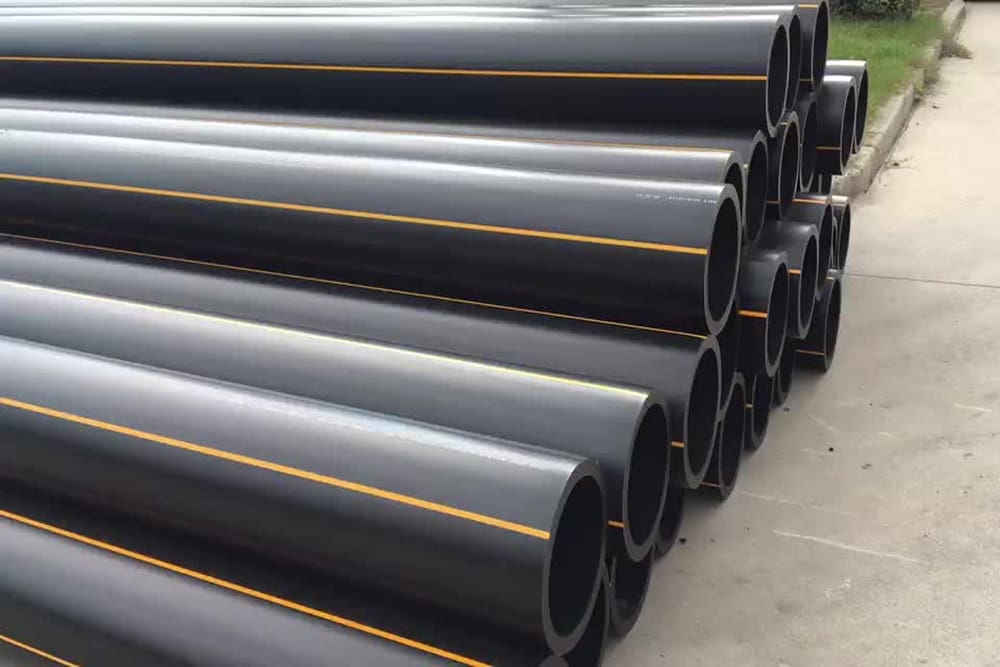

PE100 material Polyethylene is a type of plastic that is frequently utilized in plumbing applications due to the fact that it is long-lasting and inexpensive

Pipes made of polyethylene are typically yellow in color

pe pipe fittings

Couplings and pipe fittings serve the same purpose, which is to establish a safe and secure connection between two pipes

Pipes such as pe and pvc or hdpe and piping systems almost always make use of fittings in order to connect individual pipes to one another

There are many different kinds of fittings, and their applications are dependent on the kind of fitting being used

Compression fittings are by far the most frequent form of fittings that may be found

Threads are located on both ends of compression fittings, which are composed of metal and have a cylindrical shape

Because they have threads, they can be screwed on to the end of the tube

After the pipe has been pushed all the way into the compression fitting, the diameter of the fitting’s interior will have shrunk significantly

As a direct consequence of this, the inner wall of the pipe is strongly compressed against the outer wall of the fitting

This creates a secure barrier against any potential leaks

An expansion fitting is the name of a different category of fitting

In contrast to compression fittings, expansion fittings do not have an inner diameter that is reduced when a tube is placed into the fitting

Compression fittings are quite similar to expansion fittings

Instead, a modest increase in diameter is made all the way around

Because of this expansion, there is now more room between the pipe and the fitting as the diameter continues to grow

This makes available more room for the movement of fluids

pe100 pressure rating

The rating of pressure for PE100 is 15 PSI

This implies the PE-100 can handle water pressures of up to 15 pounds per square inch

If you have any worries about PE-100’s ability to sustain the pressure you want to apply, you should select a different material

If you opt to use PE-100, however, you should apply only a few drops at a time

PE-100 should not be overfilled; otherwise, it may cause damage and leaks

PE-20 has a pressure rating of 20 psi

PE-20 can handle up to 20 lb/in2 of pressure

Similarly, if you are uncertain as to whether the pressure can withstand the pressure you apply, you should search elsewhere

If you opt to use PE, however, you should only fill the tank halfway

Overfilling PE-20 might result in damage and leakage

25 psi The pressure rating of PE-25 is 25 PSI

These tanks can handle up to 25 pounds per square inch of pressure

If you have any reservations regarding the fuel tank’s ability to bear the applied pressure, you should search elsewhere

However, if you are seeking PE-25, you may only fill 1/3 of the container

An overfilled tank might result in damage and leakage

30 psi 30 psi is indicated for PE-30

The highest force that these tanks can withstand is 30 pounds per square inch

If you are uncertain about PE-30’s pressure rating, you should search elsewhere

However, if you need a fuel tank, the PE-30 is an excellent option

35 psi 35 psi is indicated for PE-35

These tanks are rated at 35 pounds per square inch

If you have any worries regarding the strength of Pe-35, you should look for anything different

However, these tanks are excellent for individuals in need of a solid and resilient container

pe100 hdpe

Polyethylene-based PE100 plastic is a suitable alternative to HDPE pipes

Polyethylene is available in many sizes, shapes, and densities

It is a versatile substance utilized in numerous sectors

PE100 polyethylene is exceptionally durable and flexible

It is FDA-approved and commonly used for medical purposes

It does not emit pollutants into the soil and is safe for human consumption

HDPE pipes are costlier than PE100 plastic pipes

Despite the fact that both types of pipes are affordable, HDPE pipes are more expensive due to their superior quality and durability

HDPE pipes are heavier than PE100 plastic pipes

HDPE pipe weighs approximately four pounds per foot, but PE100 weighs only one pound per foot

This means that transporting a large number of pipes will be challenging due to their weight

HDPE pipes are less user-friendly than PE100 polymers

There are numerous limitations to HDPE pipes

For instance, they cannot be bent or drilled through

Additionally, you cannot connect fittings to pipe ends

until the end of the pipe is cut off

it is more challenging to clean HDPE pipe than PE100 plastic

If something is dropped on an HDPE pipe, the entire pipe will become stained and must be cleaned

PE100 plastic, on the other hand, is easy to clean because it is lightweight and nonstick

Utilize a drip irrigation method Drip irrigation systems are the most effective method for watering plants

They allow you to control how much water each plant receives and prevent overwatering

The initial expenditure required for a drip irrigation system is the method’s largest drawback

If you intend to use the system for an extended period of time, it may be worthwhile to invest in a quality drip irrigation system