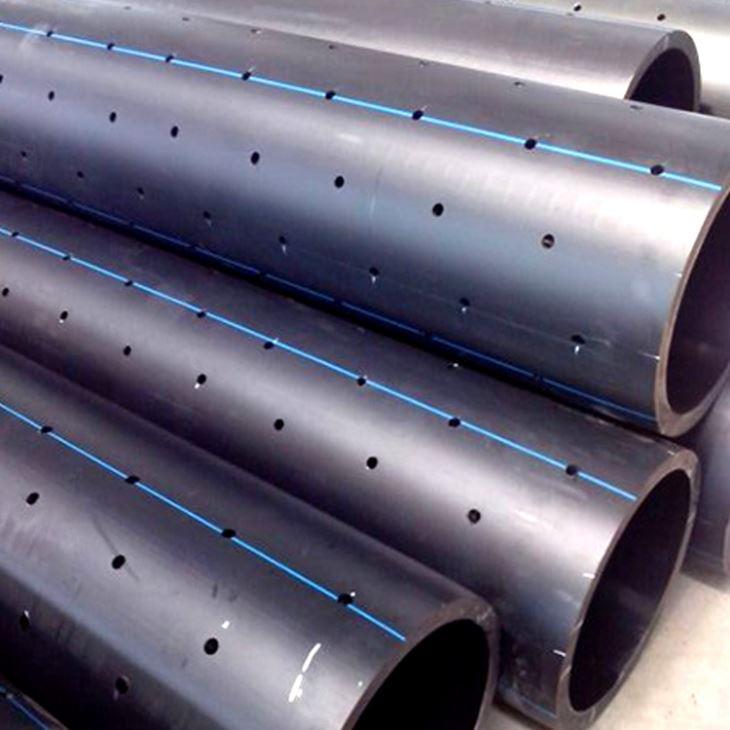

hdpe pipe supplier uk have all ranges of pipes. The polyethylene tube is in plain language. Made of polyethylene. And the same is the material of polyethylene. Which adds to the tube properties. Which has the advantages and benefits of the popularity of polyethylene pipes.

Polyethylene pipes have many advantages. High quality, reliable polyethylene pipe and fittings, ease of loading and transportation of polyethylene pipe and fittings, due to their relatively low weight, quick and easy installation, has made polyethylene types the best choice in a variety of projects. Also, the polyethylene tube has a low bending radius. And at very low temperatures, it has excellent resistance to impact and pressure. Acidic and gamma-containing environments, as well as many solutions and chemicals, do not affect polyethylene. This is one of the most important advantages of a polyethylene tube and polyethylene joints.

Polyethylene materials used to produce polyethylene pipes are different from the type of polyethylene used for the production of other polyethylene products. Polyethylene is available in various grades. And each of these types of polyethylene materials is used for various applications. pe pipes is most used. gps pipe is also most used. All factories of hdpe fabricate pe pipe fittings too.

HDPE Pipe Specifications

Polyethylene pipe and polyethylene fittings have a lower weight than other types of pipes, such as steel pipes and concrete pipes, which makes it easy to carry, load and install a flexible polyethylene pipe. Resistance to very low temperatures, strength and durability of tensile stresses and high elasticity of polyethylene allow the user to carry and install polyethylene pipes for the implementation of various industrial projects.

Polyethylene pipe and polyethylene fittings have a lower weight than other types of pipes, such as steel pipes and concrete pipes, which makes it easy to carry, load and install a flexible polyethylene pipe. Resistance to very low temperatures, strength and durability of tensile stresses and high elasticity of polyethylene allow the user to carry and install polyethylene pipes for the implementation of various industrial projects.

High resistance of the polyethylene pipe against impact, eliminates the need for higher pipe pressures and polyethylene fittings and the purchase of anti-shock equipment. This feature in large industrial projects makes it easy to run and reduces the cost of the operation, while reducing the waste to zero. This can be a very good reason for replacing the pipe and the polyethylene fittings with a variety of concrete and metal pipes.

HDPE UK Manufacturers Prices

Since the mid-1950s, the production of polyethylene pipes has come to the fore with its amazing properties. These pipes, also known as PE tubes, have been expanded rapidly with numerous applications for which it was expressed. And because of its adaptability and its advantages over iron, steel and cement pipes were used.

Indeed, the unique characteristics and characteristics of plastics, and in particular polyethylene, only quickly changed the process of its use and application in the industry.

HDPE Pipe Companies for Export from UK

- Advanced Pipeline Supplies Ltd

- Agru America, Inc.

- GD Environmental Services

- Pipestock Limited

- Dura-Line Corp

- Durapipe – an Aliaxis Company

- MGA Controls Limited

- Marley Plumbing & Drainage Ltd.

Cheapest prices of HDPE Pipes in UK

The flexibility of the polyethylene pipes will save them the cost of installing them. This unmatched technology in the longitudinal direction requires less connections. And can be connected to each other by using texture techniques and electrophyenes or mechanical joints.

In November 1953, Professor Carl Ziegler and his colleagues succeeded in polymerizing ethylene in the presence of an organo-metallic catalyst under low pressure and temperature conditions. Professor Ziegler, along with Italian chemist Julio Nata, won the Nobel Prize in chemistry in 1963 for this discovery. Only one month after the discovery, Dr. Otto Horn, director of the Hawkhis Chemical Plant’s research team, received basic samples of polyethylene for testing and evaluation. The The first experimental 10-tonne polyethylene production plant was set up in early 1954 in Frankfurt am Main, Germany.

Your comment submitted.