hdpe pipe manufacturer philippines are good products. Polyethylene is a variety of thermoplastic polymers. This means that it reaches its melting point to the liquid state, and when it reaches the freezing point, it becomes solid. Polyethylene is a chemical synthesis of ethylene, which usually comes from the combination of crude oil and natural gas. Some of its unofficial names are polythene or polyethylene, in addition to the term PE. Polyethylene is often used to make plastic compounds. To be used purely. This material is used in a wide range of applications. pvc pipe philippines manufacturer can product good pipes. pvc supplier philippines almost product HDPE too.

Best HDPE Pipe suppliers in Manila

Polyethylene comes from oil. Almost every 1.75 kg of crude oil produces one kilogram of heavy polyethylene. which is a heavy duty polyethylene capable of recycling. And it should be said that the most common and most used and perhaps the first kind of plastic that was produced was heavy polyethylene (HDPE). The molecular moiety in this type of polymer is compressed. which causes it to increase its density. Therefore, flexibility is greatly reduced. Although this type of polymer has less impact resistance than light polyethylene. its resistance to chemicals, as well as its resistance to fragile environmental stresses, is good. Therefore, this kind of polymer is used in a variety of commercial products. such as fuel storage containers, open air chairs, toys, toys, high pressure water pipes, sewage pipelines and ducts.

HDPE Pipe Exporters and Importers in Philippines

WEIDA is a company registered in the Malaysian Stock Exchange since 2001. It has many projects and workplaces in Malaysia, Philippines and the Middle East. By providing customized solutions and personalized services, the company meets the needs of urban and industrial customers. other important companies are as follows. hdpe pipe price list philippines 2017 are as follows.

- Chongzhou Minjiang Plastic Co., Ltd. Xinjiang Branch

- Tianjin Ace Flowtech Co., Ltd.

- Henan Jiashang Information Technology Co., Ltd.

- Anhui Skyley Import And Export Co., Ltd.

- Henan Hesu Construction Material Co., Ltd.

- Tianjin Jintong Pipeline Engineering Co., Ltd.

- Weifang Palconn Plastics Technology Co., Ltd.

- Chongzhou Minjiang Plastic Co., Ltd. Xinjiang Branch

- Shanxi Midas Industrial Co., Ltd.

- Shenyang Chunxi Trade Co., Ltd.

- Urumqi Jingwei Tongda Commerce And Trade Co., Ltd.

- Shandong Yost Economic And Trade Co., Ltd.

- Huayang Zhongyuan (Tianjin) Industrial Group Co., Ltd.

- Tianjin Ace Flowtech Co., Ltd.

- Hunan Qianxin Pipe Industrial Co., Ltd.

Export Price of HDPE Pipe for Water Supplying

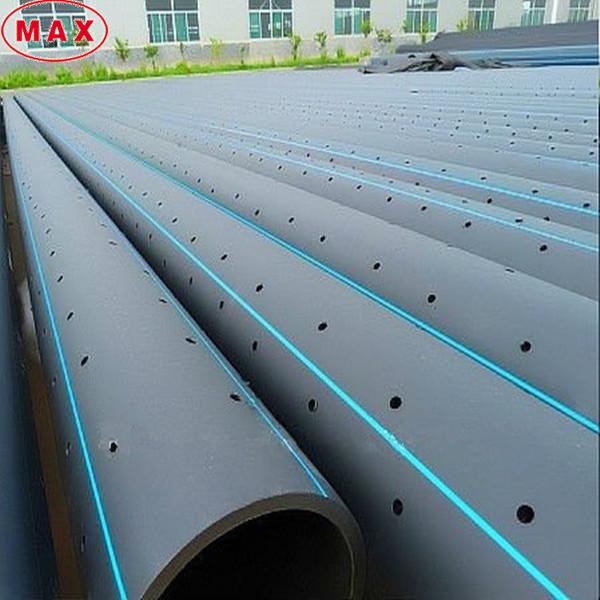

Polyethylene pipes have different types that are used according to their application. The most widely used polyethylene pipes are polyethylene water pipes. The polyethylene pipe is a black water supply that is distinguished by a blue line from other pipes. Their main application is in water supply and distribution. Important characteristics of polyethylene water supply can be noted for its strength and lightness, lack of corrosion and non-degradation. The polyethylene water pipe also has a long life span and is economically feasible.

Since microorganisms do not damage the polyethylene pipe, they are also suitable for drinking water. This product is available in different pressures on the market and buyers are buying according to their needs. These advantages have made the polyethylene water pipe replaced by metal and concrete pipes. The main application of polyethylene pipes is water supply for the transfer of water outside the city or within the city for main branches.

Water Pipes Producers Companies in 2019

HDPE pipe producers are able to provide water pipes. Water pipes play an important role in the transmission of water and in the water supply network. Polyethylene water pipes have a diameter of 16 to 315 mm and are produced in pressure classes 4 to 25 atmospheres (PE100, PE 80). These pipes, regardless of thickness and work pressure, are divided into three different types according to the materials.

PE 63 type of polyethylene water pipe is not used today and is outdated. It has a thicker and more weight than the other two models, and its production cost is very high and does not cost much.

for PE 80 producing this model, manufacturers have found that by increasing the density of materials, more pressure can be introduced into the product, reducing its weight and thickness and pricing below the PE 63 model. After the PE 63 model, it was much better and more efficient.

PE 100 polyethylene pipe is made of the finest raw material, with a higher load and a lower weight and thickness, it can withstand a lot of work. In the previous models, sunlight caused the pipe to be sealed, and one of the disadvantages of the polyethylene water pipe was the same reason, which is being addressed in this model. PE 100 is ultraviolet (UV), and sunlight has no effect on it.

Your comment submitted.