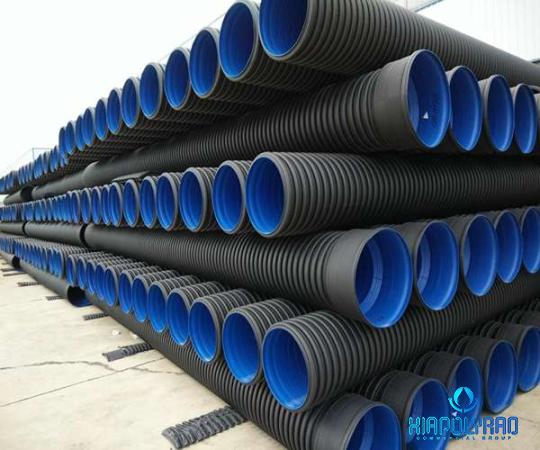

Black corrugated pipes have gained significant popularity in various industries due to their durability, flexibility, and cost-effectiveness. These pipes find applications in various sectors, including agriculture, construction, drainage systems, and infrastructure projects. This article explores the essential aspects to consider when selecting black corrugated pipe sizes for your specific needs. 1. Diameter: One of the most critical factors to consider when choosing black corrugated pipe sizes is the diameter. The diameter determines the capacity of the pipe to carry and disperse fluids or solids, making it crucial for efficient flow management.

.

Common black corrugated pipe diameters range from 3 inches to 60 inches, offering a wide range of options to suit various applications. 2. Wall Thickness: The wall thickness of black corrugated pipes signifies its structural integrity and resistance to pressure. Depending on the intended use, different wall thicknesses may be required. Thicker walls are generally preferred for applications in high-pressure environments or areas with heavy soil loads. Conversely, thinner walls may be suitable for low-pressure applications or when weight reduction is a consideration. 3. Length: The length of black corrugated pipes is another important aspect to consider. Standard lengths typically range from 10 to 20 feet, although custom lengths can be manufactured to fit specific project requirements.

Common black corrugated pipe diameters range from 3 inches to 60 inches, offering a wide range of options to suit various applications. 2. Wall Thickness: The wall thickness of black corrugated pipes signifies its structural integrity and resistance to pressure. Depending on the intended use, different wall thicknesses may be required. Thicker walls are generally preferred for applications in high-pressure environments or areas with heavy soil loads. Conversely, thinner walls may be suitable for low-pressure applications or when weight reduction is a consideration. 3. Length: The length of black corrugated pipes is another important aspect to consider. Standard lengths typically range from 10 to 20 feet, although custom lengths can be manufactured to fit specific project requirements.

..

Longer lengths reduce the need for additional connections, minimizing the potential for leakage and ensuring a seamless and efficient flow of materials. 4. Flexibility: Black corrugated pipes are known for their flexibility, allowing for easy installation and maneuverability around obstacles. However, the level of flexibility can vary depending on the pipe’s diameter and wall thickness. It’s important to consider the expected level of flexibility required for your project to ensure ease of installation, especially in tight spaces or complex terrain. 5. Material Composition: Black corrugated pipes are typically made from high-density polyethylene (HDPE) or polypropylene (PP) materials, ensuring excellent durability and resistance to corrosion, chemicals, and UV exposure. Understanding the material composition is important, as it directly affects the pipe’s lifespan and performance in different environmental conditions.

Longer lengths reduce the need for additional connections, minimizing the potential for leakage and ensuring a seamless and efficient flow of materials. 4. Flexibility: Black corrugated pipes are known for their flexibility, allowing for easy installation and maneuverability around obstacles. However, the level of flexibility can vary depending on the pipe’s diameter and wall thickness. It’s important to consider the expected level of flexibility required for your project to ensure ease of installation, especially in tight spaces or complex terrain. 5. Material Composition: Black corrugated pipes are typically made from high-density polyethylene (HDPE) or polypropylene (PP) materials, ensuring excellent durability and resistance to corrosion, chemicals, and UV exposure. Understanding the material composition is important, as it directly affects the pipe’s lifespan and performance in different environmental conditions.

…

6. Regulatory Compliance: Ensure that the black corrugated pipes meet regulatory standards and certifications specific to your region or industry. Compliance with standards such as ASTM F405/F667 or AASHTO M252/M294 is crucial to ensure safety and reliability in your application. Conclusion: Selecting the appropriate black corrugated pipe size is crucial for a successful project. Considering factors such as diameter, wall thickness, length, flexibility, material composition, and regulatory compliance will help you make an informed decision that guarantees optimal performance and longevity. Consult with industry professionals and suppliers to identify the most suitable black corrugated pipe size for your specific needs, ensuring the success of your project.

6. Regulatory Compliance: Ensure that the black corrugated pipes meet regulatory standards and certifications specific to your region or industry. Compliance with standards such as ASTM F405/F667 or AASHTO M252/M294 is crucial to ensure safety and reliability in your application. Conclusion: Selecting the appropriate black corrugated pipe size is crucial for a successful project. Considering factors such as diameter, wall thickness, length, flexibility, material composition, and regulatory compliance will help you make an informed decision that guarantees optimal performance and longevity. Consult with industry professionals and suppliers to identify the most suitable black corrugated pipe size for your specific needs, ensuring the success of your project.

Your comment submitted.