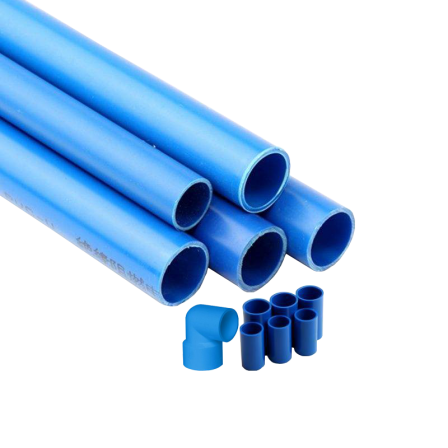

Plastic pipes can be used for hot and cold water plastic plumbing pipe. One of the benefits of this type of piping is the lack of rust and accumulation of sediment.For more information, please stay with us by the end of the article.

- Can we use copper compression fittings on plastic pipe?

- Is it possible to mix plastic and metal plumbing?

- Can you connect plastic pipe to metal pipe?

- Different types of metal pipes and their uses

- What are the properties of plastic pipes?

- How to use plastic pipes in building?

- Which sellers have high quality products at low prices?

- What are the plastic fittings made of?

- Which plastic pipes are better?

Can we use copper compression fittings on plastic pipe?

Sometimes when installing communication systems, it is necessary to combine elements made of different materials. Especially in most construction activities, there is a connection. Plastic pipes with metal, which you can use in different ways. Usually, when building plumbing, sewage or other systems, manufacturers try to use the same materials.However, in some places where the pressure of the pipes is high, copper pipes can be lubricated because they are more weight-bearing than plastic pipes and are more resistant to fracture, and can be welded and combined with a plastic pipe. It can be used.Polyvinyl chloride or pvc pipe is a very common type of plastic. At present, it is one of the most valuable products of the petrochemical industry.

Sometimes when installing communication systems, it is necessary to combine elements made of different materials. Especially in most construction activities, there is a connection. Plastic pipes with metal, which you can use in different ways. Usually, when building plumbing, sewage or other systems, manufacturers try to use the same materials.However, in some places where the pressure of the pipes is high, copper pipes can be lubricated because they are more weight-bearing than plastic pipes and are more resistant to fracture, and can be welded and combined with a plastic pipe. It can be used.Polyvinyl chloride or pvc pipe is a very common type of plastic. At present, it is one of the most valuable products of the petrochemical industry.

Is it possible to mix plastic and metal plumbing?

Of course, in some places where heat, pressure and temperature are in very poor condition, it is better to use metal pipes, and in some places plastic pipes cannot be used because they are too tilted and because of the pipes. Flexible metal can be welded with plastic pipes and where plastic pipes are manufactured to standards that allow the sediment to not accumulate in water and not deteriorate water quality. Some of the less reliable sources emphasize the quality of copper and metal water pipes, which are not very likely to be used. They are a necessity at times, so the priority of plastic pipes should be as high as possible.pex pipe There are lathes used in building plumbing.

Of course, in some places where heat, pressure and temperature are in very poor condition, it is better to use metal pipes, and in some places plastic pipes cannot be used because they are too tilted and because of the pipes. Flexible metal can be welded with plastic pipes and where plastic pipes are manufactured to standards that allow the sediment to not accumulate in water and not deteriorate water quality. Some of the less reliable sources emphasize the quality of copper and metal water pipes, which are not very likely to be used. They are a necessity at times, so the priority of plastic pipes should be as high as possible.pex pipe There are lathes used in building plumbing.

Can you connect plastic pipe to metal pipe?

In general, plastic pipes are highly resistant to acids, salts, liquids and corrosive gases. In the case of erosion, the degree of resistance of the plastic pipes depends on the type of fluid being transported through the pipe and the conditions of service and system.The corrosion resistance of plastic pipes varies with the concentration of certain chemicals. For example, polyethylene pipes can transfer 70% sulfuric acid at 23 ° C (73 ° F), while it is not suitable for 95% sulfuric acid transfer. Temperature is also an important determinant of corrosion resistance of plastic pipes. For example, some polyethylene pipes that are suitable for transporting gases containing nitrogen oxides at 23 ° C should not be used to transport these gases at 50 ° C. The specific formulation of a particular plastic material can also be used to determine the overall resistance of the material to corrosive chemicals and their concentration but Ductile steel pipe is a pressure pipe used for piping drinking water and wastewater and is covered by spherical graphite cast iron and ductile metal that have lost their credibility with the progress of the old cast iron pipe industry. It has higher strength and high resistance to fracture, but it is likely to break.Since some places are subject to pressure and impact, it is not possible to use a plastic pipe and the metal pipe should be used so where the metal pipe is needed and where the pressure is not high the plastic pipe can be used and It welded these two types of pipes together and made the fitting of the desired location.plastic pipe fittings catalogue This is a notebook of tube photos that is sorted by color and inch and may have self-contained pieces in a cupboard and used as a catalog.

Different types of metal pipes and their uses

steel pipes are in recent times one of the maximum widely used pipes in business plumbing systems. In truth, those pipes are one of the fine options for manufacturing piping structures in commercial and refinery processes because of their high power, warmth resistance in addition to relative resistance to corrosion. numerous forms of steel pipes are utilized in commercial and process piping systems, refineries, petrochemical plant life, oil and gas transmission lines, water transmission systems, installation structures, boilers, air conditioners and greater.

steel pipes are in recent times one of the maximum widely used pipes in business plumbing systems. In truth, those pipes are one of the fine options for manufacturing piping structures in commercial and refinery processes because of their high power, warmth resistance in addition to relative resistance to corrosion. numerous forms of steel pipes are utilized in commercial and process piping systems, refineries, petrochemical plant life, oil and gas transmission lines, water transmission systems, installation structures, boilers, air conditioners and greater.

numerous styles of steels with different chemical composition and hence exceptional bodily and mechanical properties are used in the manufacture of metal pipes. The sort of metallic used inside the manufacture of those pipes generally determines the applications and provider conditions for which the pipe is selected. for that reason, within the method of designing and manufacturing commercial plumbing systems, the primary and principal step in the design procedure is selecting the proper fabric for pipes and other plumbing equipment.

In truth, quite a few studies has been done in latest years to broaden the metallic used in the design and manufacture of piping systems. The statistics amassed has brought about the belief that if the technical traits, intercourse and physical and chemical residences of the pipes and system used in the piping device are carefully taken into consideration, the long-term conduct of the system is notably predictable. .

there are numerous methods to produce steel pipes. usually, those pipes are divided into two categories: Welded and Seamless, in step with the method used to fabricate them.

Welded Pipe Seamless Pipes

metal pipes and welding are used to make such pipes. In these tubes, the sheet is first formed right into a tube after which the joint is joined with the aid of welding. Jointed pipes are normally synthetic in two methods.

Longitudinal seam weld

on this approach, the specified sheet is ready with dimensions of equivalent duration and width equal to the fringe of the pipe after which is bent alongside its length and formed with U&O or roller bending or press bending machines. The seam of the tube is marked with a C electrode by way of unique computerized devices inside and outside. those tubes might also have one or weld seams.

Spiral joints:

To make these pipes, the sheet is rolled after which bake thru the edges of the pipes and inserted into the bending system and spirally formed into tubes and without delay after the seam is fashioned with the gadget it’s far routinely welded to the electrode.

(SEAMLESS)

those pipes are usually manufactured by means of rotary punching method of molten spherical ingots and no weld seams.

no longer on their frame. for this reason, their strength and first-class are better than those of welded steel pipes. Seamless pipes are used for diverse industrial applications, particularly whilst excessive pressure is carried out to the machine. utilized in industries along with petroleum, gas and petrochemical, the development of strain vessels, boilers and hydraulic circuits.

What are the properties of plastic pipes?

The most important feature of plastic and polymer tubes is their high resistance to wear and corrosion. Polyethylene pipe and other polymer tubes can remain stable under acidic and alkaline conditions and in the presence of harmful chemical salts. The walls of these pipes do not wear out due to the fluid passing through the pipe and can therefore continue working for long periods.Another important factor for plastic and polymer tubes is their thermal stability. Almost all polyethylene pipes are resistant to very high temperatures. On the other hand, these pipes will never freeze. Some chemicals increase the temperature of the pipes, which is why plastic and polymer pipes can stay well under these conditions.One of the simplest features of a plastic pipe is its smooth, smooth wall. This feature does not cause deposition or any other mass in the wall and the pipes can maintain their performance; on the other hand, the friction in the pipes with a smooth wall is greatly reduced and the fluid can flow well through the pipe. Pass.The plastic and polymer tubes are lightweight and therefore easy to transport; also the use of these types of tubes will reduce many additional costs. Physical resistance of plastic and polymer tubes is another major property of these tubes.

The most important feature of plastic and polymer tubes is their high resistance to wear and corrosion. Polyethylene pipe and other polymer tubes can remain stable under acidic and alkaline conditions and in the presence of harmful chemical salts. The walls of these pipes do not wear out due to the fluid passing through the pipe and can therefore continue working for long periods.Another important factor for plastic and polymer tubes is their thermal stability. Almost all polyethylene pipes are resistant to very high temperatures. On the other hand, these pipes will never freeze. Some chemicals increase the temperature of the pipes, which is why plastic and polymer pipes can stay well under these conditions.One of the simplest features of a plastic pipe is its smooth, smooth wall. This feature does not cause deposition or any other mass in the wall and the pipes can maintain their performance; on the other hand, the friction in the pipes with a smooth wall is greatly reduced and the fluid can flow well through the pipe. Pass.The plastic and polymer tubes are lightweight and therefore easy to transport; also the use of these types of tubes will reduce many additional costs. Physical resistance of plastic and polymer tubes is another major property of these tubes.

How to use plastic pipes in building?

Building plumbing is divided into three main subgroups, namely water and gas piping and sewage piping, each of which has its own separate subgroups.

Building plumbing is divided into three main subgroups, namely water and gas piping and sewage piping, each of which has its own separate subgroups.

water piping:In the case of water piping, abnormal performance results in reduced water pressure or low boiler efficiency.Water piping may be made of galvanized iron pipes or galvanized steel pipes, copper pipes, plastic pipes, brass pipes, cast iron pipes, galvanized pipes, ferrous or other pipes made of materials approved for the cold water system. The choice of materials used in pipe making depends on:

Amount of water to be supplied.

water pressure

Corrosion or rust factor for different pipe types at different temperatures

Cost

Pipe accessibility with the desired sex

Which sellers have high quality products at low prices?

Polyethylene pipes are made of pe40, pe63, pe80 and pe100 materials. The final price of these pipes varies depending on the purity of the raw material for pipe production. Material purity means the amount of raw material mixed with the waste material. The scrap materials are made from grinding consumed polyethylene pipes. Polyethylene pipes made of scrap materials such as granules or compds have their own applications. For example, sheaths are used for power cables or fiber optic. But for high pressure sensitive applications or for projects where welding of PE is required, high quality pipes should be used. Most PE producers use their own waste line in their production pipes. According to the above mentioned prices of polyethylene pipes vary from 2000 toman to 7000 toman in the market.When buying plastic pipes, you should either look for quality or look for the price, which, if said to be cheap, should be questionable in its raw materials and quality in terms of quality, but high quality plastic pipes can be found in Stores have gotten better and better quality, but because the quality of these pipes is not attainable by simple tests, or experience has to be found to be high quality plastic pipes, or by sophisticated tests, then we cannot name a store. Those stores have quality products and reasonable prices.

Polyethylene pipes are made of pe40, pe63, pe80 and pe100 materials. The final price of these pipes varies depending on the purity of the raw material for pipe production. Material purity means the amount of raw material mixed with the waste material. The scrap materials are made from grinding consumed polyethylene pipes. Polyethylene pipes made of scrap materials such as granules or compds have their own applications. For example, sheaths are used for power cables or fiber optic. But for high pressure sensitive applications or for projects where welding of PE is required, high quality pipes should be used. Most PE producers use their own waste line in their production pipes. According to the above mentioned prices of polyethylene pipes vary from 2000 toman to 7000 toman in the market.When buying plastic pipes, you should either look for quality or look for the price, which, if said to be cheap, should be questionable in its raw materials and quality in terms of quality, but high quality plastic pipes can be found in Stores have gotten better and better quality, but because the quality of these pipes is not attainable by simple tests, or experience has to be found to be high quality plastic pipes, or by sophisticated tests, then we cannot name a store. Those stores have quality products and reasonable prices.

What are the plastic fittings made of?

One of the most important advantages of polyethylene pipes compared to other types of pipes is its easy connectivity. Fittings are used in such cases as changing the angle of the pipeline route, changing the diameter, connecting the pipe parts and so on. In various applications, polyethylene pipes include screw fittings, belts, gear fittings, high pressure polyethylene fittings for butt welding, polyethylene sewage fittings, electro fusion and handheld fittings.Very good resistance of polyethylene joints to fracture and cracking due to external pressures

One of the most important advantages of polyethylene pipes compared to other types of pipes is its easy connectivity. Fittings are used in such cases as changing the angle of the pipeline route, changing the diameter, connecting the pipe parts and so on. In various applications, polyethylene pipes include screw fittings, belts, gear fittings, high pressure polyethylene fittings for butt welding, polyethylene sewage fittings, electro fusion and handheld fittings.Very good resistance of polyethylene joints to fracture and cracking due to external pressures

High resistance to pressure and impact

Resistance to chemicals

Corrosion and wear resistant

Excellent resistance to vibrations caused by earthquakes

Rust resistant

Smooth and smooth interior and exterior wall, non-fouling and low pressure drop due to internal surface frictionHigh flexibility, very low installation cost, fast running speed and no need for heavy machinery when running polyethylene pipelines.Plastic pipe fittings come in a variety of types, depending on the type of material used, some of which are made of the same plastic material and some are made of copper and metal.plastic hot water pipe That are used to provide hot water in the bathroom, toilets and wherever necessary and make hot water available at that point and location.

Which plastic pipes are better?

The best PE pipe is the best brand of PE pipe. The manufacturing process is very important and the quality of the PE pipe is important in the manufacturing process. The quality of the best PE is primarily related to the type of raw material used, in the production of high quality PE the recycled materials are not used at all, and they are entirely new and used. The standard text states that the same pipe materials can be produced at a rate of 5% but are not used to produce the best quality PE and waste pipe. The best polyethylene pipe, apart from the use of suitable raw materials, must be manufactured with modern, well-equipped equipment and production lines that produce the pipe in the best possible manner and have a perfectly smooth surface (we recommend the production line equipment for study). The polyethylene pipe line acts as a single body and must work in harmony with each other so that the polyethylene pipe is of high quality.Production of high quality polyethylene pipe is in addition to the use of the appropriate raw materials and excellent production line in the form of warehousing and transportation, and if this section does not comply with the instructions, the pipe may suffer serious and irreparable damage. Affect the pipe operator.plumbers pipe It is used to provide water or to transport wastewater from home.

The best PE pipe is the best brand of PE pipe. The manufacturing process is very important and the quality of the PE pipe is important in the manufacturing process. The quality of the best PE is primarily related to the type of raw material used, in the production of high quality PE the recycled materials are not used at all, and they are entirely new and used. The standard text states that the same pipe materials can be produced at a rate of 5% but are not used to produce the best quality PE and waste pipe. The best polyethylene pipe, apart from the use of suitable raw materials, must be manufactured with modern, well-equipped equipment and production lines that produce the pipe in the best possible manner and have a perfectly smooth surface (we recommend the production line equipment for study). The polyethylene pipe line acts as a single body and must work in harmony with each other so that the polyethylene pipe is of high quality.Production of high quality polyethylene pipe is in addition to the use of the appropriate raw materials and excellent production line in the form of warehousing and transportation, and if this section does not comply with the instructions, the pipe may suffer serious and irreparable damage. Affect the pipe operator.plumbers pipe It is used to provide water or to transport wastewater from home.

Your comment submitted.