Polyethylene pipe sizes | The purchase price, usage, Uses and properties

The difference between a polyethylene pipe is durability and tightness also the place we can use them

Polyethylene piping with only one wall

This product is one of the most popular examples of its kind in the nation due to the vast range of uses to which polyethylene pipes can be put

The advantages of polyethylene pipes are their low weight, portability, resistance to corrosion and wear, and ease of installation and removal

Nowadays, there are a wide variety of polyethylene pipes available on the market

These tubes may have one or two layers, thus the names single-wall and double-wall polyethylene pipes

Executive-level projects requiring the use of polyethylene pipe need careful consideration of the options available, and an understanding of the distinction between single-wall and double-wall polyethylene pipe is essential

due to the fact that the context of each industrial project’s pipe installation and use will vary

So, we’ll split this article up and talk about the most important parts of each of these things in their own sections

Common polyethylene pipes just have one wall

Single-walled pipes are sometimes known as high-pressure polyethylene pipes

Allowed fluids are carried under pressure via these conduits

It is possible to categorize single-walled polyethylene pipes, such as PE80 and PE100, into several groups depending on their basic ingredients and end uses

These pipes come in a range of diameters and operating pressures and are made to the strictest domestic and international requirements

For instance, PE80 or white PE100 materials combined with masterbatch can be used to create pipes or irrigation tapes with a small diameter that are put to use in agriculture for drip irrigation or pressure irrigation in gardens

Water supply and fire protection systems both employ single-walled polyethylene piping

The most reputable specifications for single-wall polyethylene pipe are DIN 8074, DIN 16963, and Isiri 1331

Some characteristics that define single-wall polyethylene pipes are as follows: Specifications for Polyethylene Pipe with a Single Wall Possibility of use on hilly terrain high resistance to breaking or cracking Welded seams can withstand temperatures up to 80 degrees Celsius

Temperature resistance down to -70 degrees Celsius It withstands pressures of up to 16 bar

Chemical resistance in any situation The ability to withstand oxidation and corrosion Single-wall polyethylene pipe is often used in the form of Single-wall polyethylene pipe is most often used in oil, water, gas, sewage, and agricultural applications, but it is also commonly used in sewage systems, flood control, and drainage systems

The following are some of the most common applications for these pipelines

Many different substances, including chemicals, food, slurries, compressed air, and vacuum systems, are conveyed

We fix drainage issues for houses, businesses, and government buildings of all shapes and sizes

Driveways, parking lots, roofs, walkways, and parking garages should all have their overflow and rainwater drained

One reason for these pipes is to take trash from homes and businesses to the city’s sewer system

Single-walled polyethylene pipes may be used as float supports because of their light weight and high resistance to corrosion and chemical attack

The landfill leachate collection systems use single-wall polyethylene pipes to collect the liquid

A new system of double-walled polyethylene pipes is being implemented

To make a double-walled polyethylene pipe, one pipe is put inside another pipe or wrapped around an outside cover

The primary or carrier tube is the inner tube, while the outside tube is called the harness

All sewage and fluids may be transported without the need for internal pressure thanks to the special design and construction of double-walled polyethylene pipes

High resistance to external load pressure is the primary benefit of these pipes over single-wall polyethylene pipes

Single-walled polyethylene pipes are manufactured and implemented with a primary focus on resistance to the internal pressure of the fluid passing through the pipe, while double-walled polyethylene pipes are manufactured and implemented with a primary focus on resistance to the pressure of external loads

The fundamental objective of the layout is to show that double-walled polyethylene pipes have many advantages over their counterparts

There are a few popular types of double-walled polyethylene pipes, the most common being the Carrogate pipe, and the second most popular being the spiral pipe

The inside wall of a carrogate pipe is smooth, while the outside wall is serrated for added grip

The unique construction of these pipes gives them superior strength and durability

In contrast, both the inside and outside of the spiral tube are perfectly smooth

The hydraulic properties of these pipes are the result of their smooth inside space

The International Organization for Standardization (ISO) 9116-2, INSO 9116-3, the German Institute for Standardization (DIN) 16961-1, and the International Pipe Fittings Association (IPFA) 16961-2 are only some of the standards that apply to double-walled polyethylene pipe

The premium advantage mentioned before has led to the widespread adoption of these pipes in a variety of different applications

Bridge and road construction, for instance, often makes use of polyethylene spiral pipes

A new system of double-walled polyethylene pipes is being implemented

The double-walled polyethylene pipe has one pipe within another pipe or inside an outer cover

The primary or carrier tube is the inner tube, while the outside tube is called the harness

All sewage and fluids may be transported without the need for internal pressure thanks to the special design and construction of double-walled polyethylene pipes

Furthermore, M,

polyethylene pipe

Specifications of the polyethylene pipe used in construction

Polyethylene pipe, which belongs to the family of materials known as thermoplastics, has been one of the pipes that has seen the greatest amount of usage during the last half century

Because of this kind of pipe’s very high levels of changeability, resistance, and durability, it has proven to be an extremely ideal replacement for pipes made of iron, cast iron, PVC, and other materials, and it has captured a significant portion of the market

Transfer lines and pipelines made of polyethylene have been used in the oil and gas industry and the petrochemical industry for many decades

Additionally, polyethylene pipe has been utilized in the construction industry and agriculture for the transmission of water

It has been installed, and so far it has been shown to be a viable and cost-effective alternative to other pipelines

This series of pipes has been utilized in the majority of the country’s water, gas, and sewage projects during the last several years

This is despite the fact that employing polyethylene pipes provides a number of benefits

As a result of the smoothness and flatness of the inside of the polyethylene pipes, they do not get clogged in any manner

Furthermore, the polyethylene pipes do not rot or corrode over time, which means that they are acceptable for delivering drinking water and are sanitary

Polyethylene pipes are made from high-density polyethylene (HDPE), which has excellent pliability and is particularly resistant to bending

As a result, polyethylene pipes have a substantially longer service life than other pipes

PE pipe Specifications of the polyethylene pipe used in construction

In the year 1353, the national standard for polyethylene pipes was drafted and modified for the first time

In the following years, this standard was examined by commissions before being changed and eventually accepted in the year 1382

This standard provides the specifications for the properties of polyethylene (PE) pipes that are suitable for use in water transmission and construction applications with a nominal pressure ranging from 3

2 to 20 bar, a nominal external diameter ranging from 16 to 1600 mm, and a temperature range spanning from 0 to 70 degrees Celsius

The standard also includes Different kinds of pipes made of polyethylene Polyethylene pipe is used for water delivery

Polyethylene and gas pipeline Polyethylene pipes for sewage systems The pipe is sheathed in polyethylene

Pipes made of high-pressure polyethylene A pipe made of polyethylene for use in drip irrigation Polyethylene pipe is used for water delivery

Pipes made of polyethylene are frequently utilized when carrying liquids such as water and drinking water

The majority of these pipes find their most common application in the agricultural sector

producing polyethylene pipes for water supply at pressures ranging from 6 to 16 bar and for sensitive cases at pressures ranging from 20 bar in sizes ranging from 20, 25, 32, 40, 50, 63, 90, 110, 125, 140, 160, 180, 200, 225, 250, 280, 315, 355, 400, 450, 500, 560, and 630 mmPolyethylene pipes for water supply typically operate at pressures of 6 to 16 bars

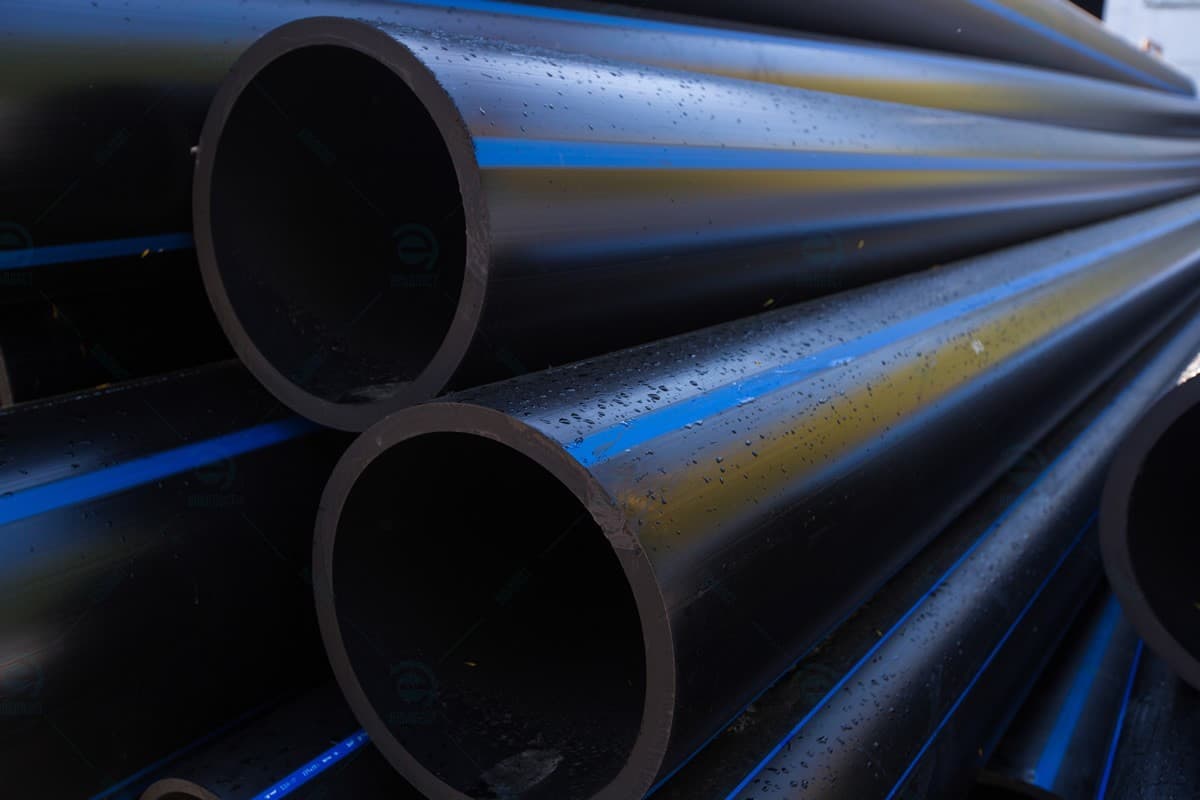

Due to the fact that concrete, cement, and even metal pipes are used in the water supply, which, over time, can lead to sedimentation and corrosion issues in the pipes themselves, polyethylene water pipes with a blue line on a black pipe roll have been developed as a solution to this problem

It is separate, and it is an excellent suggestion for dealing with these issues

The fact that this kind of pipe can be used for either drinking water or water that is used in agriculture and industry is an essential consideration when shopping for and selecting it

Polyethylene pipes, which are made for drinking water supply, are designed in terms of hygiene and health of the water, as well as not changing the taste and smell of the water, and by nature, they come to you from agricultural and industrial water supply pipes

Despite the fact that they are among the category of water supply pipes made of polyethylene, they are more expensive than other types of these pipes

Consider the PN or pipe pressure in accordance with ideal pressure conditions due to fluctuations in pressure in accordance with national standard 14427 in the field of polyethylene water pipes for agricultural and industrial products

This is required due to the fact that pressure can change

If you choose this topic carefully, it will extend the life of the pipe as well as the part of the pipe that is responsible for welding

This kind of pipe can handle temperatures up to 80 degrees Celsius and still do its job

Polyethylene pipes for sewage systems These pipes, which are typically constructed with two layers of wall, are used for the transportation of sewage

Pipes made of polyethylene used for sewage are manufactured and sold at pressures ranging from 3

2 to 5 bar, and their diameters range from 50 to 160 millimeters

Both PE grade 80 and PE grade 100 are used in the manufacturing process of these pipes

Because the body resistance of the black polyethylene pipe is 31

5 kilo newtons per square meter, it is safe to bury the pipe to a depth of 1

5 meters along the route of Mashban without worrying about the pipe being crushed

to be It has caused it to become one of the priorities for choosing sewer pipes in the category of sewage piping as a result of its high resistance to corrosion and its low cost

Polyethylene pipes should perform similarly to metal pipes, ceramic pipes, and GRP pipes, while being more coherent and resistant than PVC pipes (polica)

The residential sewer branches often make use of this particular kind of sewage pipe

It is essential to bear in mind that, compared to the size of the sewage pipe, this sort of pipe connection is not only more affordable but also more easily accessible

Polyethylene and gas pipeline Because of the nature of the application and the high level of sensitivity involved, every one of these pipes has been given the seal of approval by the National Gas Company as well as the DIN EN 1555-5 and IGS-M-PL-014-01 (2) standards

Pipes made of gas-grade polyethylene are manufactured and distributed at pressures of 12

5 and 16 bar

These pipes come in diameters of 25, 63, 90, 110, 125, 160, 200, and 225 millimeters, and their grades are either PE100 or PE80

The pipe is sheathed in polyethylene

At a pressure of between 6 and 10 bar, sheathed polyethylene pipes with diameters ranging from 20 to 400 mm may be manufactured

These pipes are used as coverings and sheaths for electric cables and wires

Pipes made of high-pressure polyethylene These pipes are manufactured at pressures ranging from 10 to 30 bar, and their diameters range anywhere from 20 to 630 millimeters

These pipes have a thickness that is larger than that of the others

You may also hear these pipes referred to as pressurized polyethylene pipes

In situations when the fluid pressure is being employed by the pump to meet the needs of the user or when a large volume of fluid is being deposited at a height, these pipes are used