The price of Polyethylene Pipe + cheap purchase

pipe made of HDPE and pipe made of PE100 polyethylene HDP pipes are of a high grade and provide a variety of benefits

HDPE pipes are often used in worldwide construction projects because of their versatility and suitability for a wide range of uses and sizes

We manufacture HDPE pipes with the requisite pressure classes Pn4-Pn32, in diameters ranging from 20 to 1200 mm and inches, and with high levels of efficiency and quality throughout the production process

There are a lot of reasons why it would be beneficial to your projects to adopt an HDPE pipe system that is risk-free

What what is an HDP tube? HDPE pipes, which are composed of polyethylene, are rather popular due to their many benefits, including their high strength and their broad range of application sectors

There are several benefits associated with HDP tubes

It is the greatest option for projects because of the dependability of the pipes and fittings, the ease with which they can be transported and loaded, and the ease with which they can be assembled

Pipes made of polyethylene offer a strong resistance to both compression and impact

It is not easily broken down by chemicals

These qualities are the primary factors that contribute to the widespread preference for polyethylene pipe and polyethylene fittings

Then, how does high-density polyethylene (HDPE) differ from other products? Pipes made of HDPE are not only sturdy but also long-lasting, flexible, and lightweight

When HDPE is mixed, there is no possibility of leakage since the fusing process generates a single HDPE system

HDPE pipe is also a more ecologically sustainable solution since it is non-toxic, resistant to corrosion and chemicals, built for a long life, and because of its flexibility, it is ideally suited for trenchless installation techniques

The many benefits of using HDP pipes 1- An easy-to-follow installation procedure and straightforward accessory assembly

2- Not broken and unaffected by the movement that occurred underneath

has a strong resistance to impact and has a rapid crack propagation

4- They have a very high degree of adaptability

As a result, they provide a convenient level of usage

5- The choice of diameter during the design phase of the project has a considerable benefit due to the low internal surface roughness of the components

6- Seawater and the movement of the sea surface have no effect on it, making it appropriate for installation on the seabed

7 The black pipe can withstand the effects of UV light

They are immune to the damaging effects of the drugs

8 It has an abrasive impact on the surface of the soil and is present in the structure of the soil

They are not affected by chemical exposure

9 Since they do not alter the odor or flavor of the water, it is permissible to utilize them in the production of drinking water

10- It is not feasible for plant roots or plants to enter the structure

Typical uses for high-density polyethylene (HDPE) water pipes

Because of its durability and superior quality, HDP pipes are used in a variety of construction projects without risk

There is a vast variety of work that can be done using HDPE pipes, which are quickly becoming the standard for use in infrastructure systems

Application areas for HDPE pipes include the following: drinking water pipelines, pressurized irrigation pipelines, hydroelectric power plants, gas pipelines, treatment plant pipelines, water treatment plants, swimming pool pipelines, cold water pipelines, compressed air pipelines, solid material conveying pipelines, chemical pipelines, geothermal pipeline covering, geothermal pipeline pipelines, solid waste methane gas discharge pipelines, solid waste discharge pipelines, marine discharge pipelines, fish feces pipelines, geothermal pipeline covering

Technical Sheet on the Weight of HDP Pipe

To obtain the hdpe pipe weight table, also known as the table for polyethylene pipe, multiply the density of the hdpe pressure pipe by the volume of the hollow cylinder

This will give you the hdpe pipe weight table

Polyethylene pipe is another name for hdpe pipe

The expansion properties of the HDPE pipe are a direct result of the heat treatment that is applied to the pipe during the manufacturing process

As a result, while constructing measurement tables for HDP pipe, it is necessary to take tolerance values into consideration

HDP pipe fittings

Simple to put together thanks to the hdpe pipe connection mechanism

In this context, the accessories that are used are significant

HDPE fittings also have the benefit of being simple to put together, which is a significant advantage

Instructions on how to connect pipes made of polyethylene

Welding or mechanical couplings are the two most common ways that polyethylene pipes and fittings are joined to one another

Pipes made of high-density polyethylene (HDPE) that are not constructed of polyethylene may have compression fittings, flanges, or other appropriate adapters that were developed specifically for the purpose of connecting them outside

When compared to the location of usage, the connecting joint offers a more convenient alternative

Method based on combinations

The kind of welding known as electrofusion (EF)

Stick welding on HDPE pipe

Welding done via electrofusion

The concept behind the electrofusion welding method is to first use electric heating to liquefy a portion of the outermost part of each of the two parts, and then use an electrofusion welding machine to fuse copper wire to the connection part of the parts that are going to be combined

This is the basic idea behind the method

Electrofusion welding is capable of being performed on pipes made of Pe100, with diameters ranging from 20mm to 1200mm

T he procedure of electrofusion welding is carried out in accordance with the DVS 2207 standard

The ass was cooked

Butt welding is the technique that is used the most nowadays to link HDPE pipes and fittings together, and it is also the most popular approach

The connection technique involves connecting the ends of the pipes that are going to be welded together by using a butt welding apparatus, then pressurizing the pipes to a specified temperature, and finally bringing the two ends closer together

The welding technology is capable of joining pipes with a diameter of up to 1200 millimeters

polyethylene pipe

What exactly is a pipe made of polyethylene? Pipe made of polyethylene is one of the most commonly utilized types of pipe in the business world

These tubes are cylindrical in shape but hollow, and they are manufactured to the needed pressure and standard in accordance with the criteria of engineering

Because of its flexibility, low settlement, high resistance, and durability when compared to other pipes on the market, polyethylene pipe is one of the pipes that has become one of the most widely used in recent years

It is used in the majority of projects and is used in the majority of applications

Yes it

Detailed A Description of the Technical Requirements for Polyethylene Pipe A member of the family of materials known as thermoplastics, polyethylene pipe has been one of the most popular and commonly used pipe materials for about half a century

This kind of pipe is very adaptable, resistant, and long-lasting

As a result, it has been able to become a very acceptable replacement for pipes made of iron, cast iron, PVC, and other materials and to occupy a significant portion of the market

Transmission lines and pipes made of polyethylene have been used for decades in the oil and gas industry, the petrochemical industry, as well as in construction and agriculture for water lines

This is because polyethylene pipes have higher resistance and durability than pipes made of iron, cast iron, PVC, and other materials

Since it was installed, it has evolved into a viable and more cost-effective alternative to other forms of plumbing

In spite of the many benefits associated with employing polyethylene pipes, this particular type of pipe has been used in the majority of the water, gas, and sewage projects carried out throughout the nation over the last few years

Due to the fact that the interiors of polyethylene pipes are smooth and flat, they do not get clogged in any manner

Furthermore, polyethylene pipes do not rot or corrode with time, which makes them acceptable for transporting drinking water and makes them sanitary

High-density polyethylene (HDPE), which is used to make polyethylene pipes, can be bent better than other types of pipes and is much more flexible

It also lasts much longer than other types of pipes

Detailed Description of the Polyethylene Pipe Specification

After being evaluated by a committee, the National Standard for Polyethylene Pipe was eventually accepted in the year 1382 after first being drafted and revised in the year 1353

Include their nominal pressures, which range from 3

2 to 20 bar, nominal outside diameters ranging from 16 to 1600 mm, and temperature ranges ranging from 0 to 70 degrees Celsius

Different kinds of pipes made of polyethylene

Polyethylene pipe is used for water delivery

Polyethylene Pipe for Gas Transport

Polyethylene pipes for sewage systems

The pipe is sheathed in polyethylene

Pipes made of high-pressure polyethylene

Polyethylene pipe is used for water delivery

Water and drinking water are both transported via this particular kind of polyethylene pipe

The majority of these pipes find their application in the agricultural industry

Polyethylene pipes for water supply typically operate at pressures between 6 and 16 bar, but can operate at pressures up to 20 bar in certain circumstances

These pipes come in a variety of sizes, including 20, 25, 32, 40, 50, 63, 75, 90, 110, 125, 140, 160, 180, and produced sizes of 200, 225, 250, 280, 315, 3505, 400, 450, 500, 560, and 630 millimeters

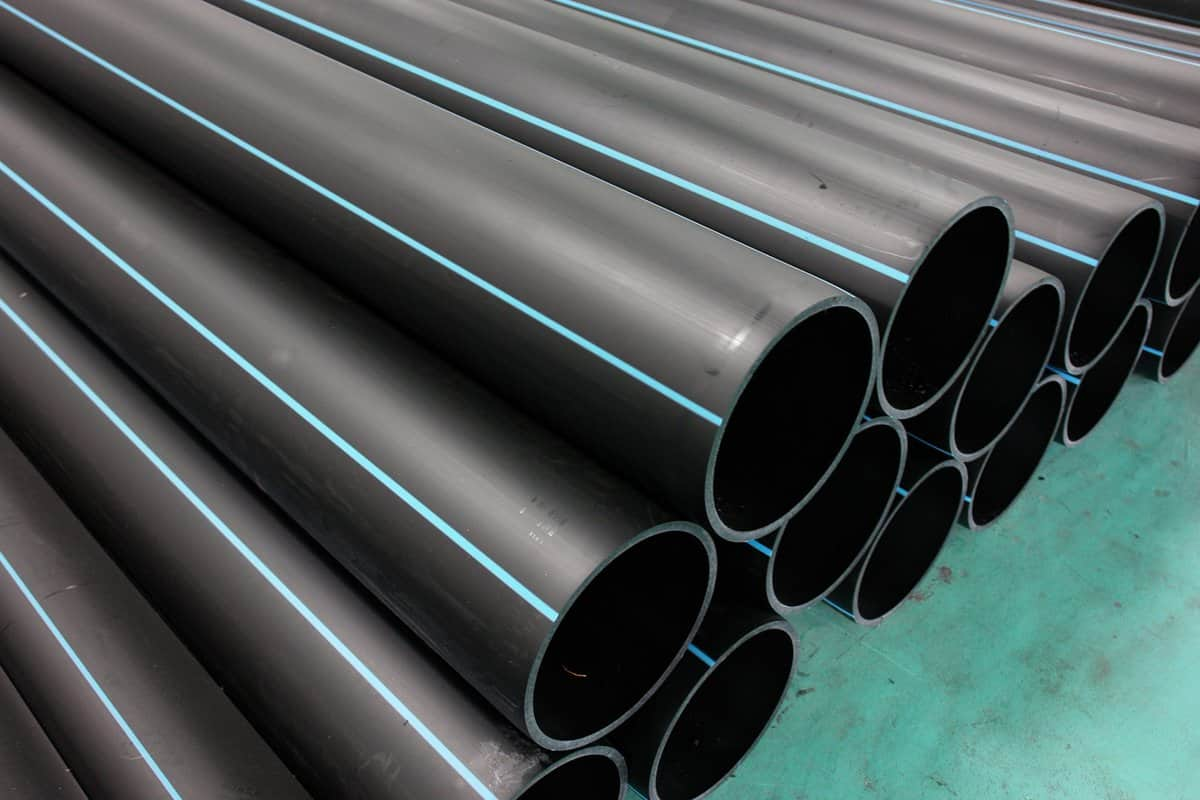

Polyethylene water pipes with blue lines on black pipes are rolled because of the use of concrete and cement, and sometimes metal pipes, in the water supply

This causes precipitation and corrosion problems in the pipes over time, so polyethylene water pipes with blue lines on black pipes are used instead

It stands on its own and is a sound recommendation with regard to these concerns

The usage of these pipes for drinking water (drinking water) as well as agricultural and industrial water is the primary motivation for purchasing and choosing them

In spite of the fact that they are part of the polyethylene water pipe category and were designed with the health and hygiene of the water in mind, as well as the fact that they do not alter the flavor or odor of the water, polyethylene pipes used for the supply of drinking water are more expensive

These pipes were also developed with the goal of maintaining the original taste and odor of the water

The national standard 14427 in the area of polyethylene water pipes for agricultural and industrial goods states that, owing to pressure changes, PN or pipe pressure is deemed to be the optimum pressure circumstance

This is the case even if the actual pressure might vary

The longevity of both the pipe and the welded portion of the pipe will be improved if you make the right decision on this problem

This kind of pipe can work well in temperatures up to 80 degrees Celsius

Polyethylene pipes for sewage systems

These pipes, which are typically constructed with two layers of wall, are used for the transportation of sewage

Polyethylene pipes used for sewage disposal are manufactured and distributed at pressures ranging from 3

2 to 5 bar, and their diameters range from 50 to 160 millimeters

These pipes are made up of PE 80 and PE 100 grade material, respectively

Because the black polyethylene pipe has a body resistance of 31

5 kg per square meter, it is safe to bury the pipe to a depth of 1

5 meters in the Marshban route without worrying that it would be crushed

Because of their high corrosion resistance and low cost, polyethylene pipes should perform similarly to metal pipes, card tubes, GRP pipes, and other types of pipes

Furthermore, polyethylene pipes should have better coherence and resistance to corrosion than PVC pipes (polica)

It has become one of Cho’s top concerns